Advantages of Using 1020 Hot Rolled Steel in Manufacturing

Introduction

1020 hot rolled steel, known for its excellent balance of strength and ductility, is a low carbon steel with a nominal carbon content of 0.2%. It is widely used in a variety of applications due to its formability, weldability, and machinability. Understanding the advantages of 1020 hot rolled steel is crucial for manufacturers looking to select the right material for their production needs. This steel grade’s properties make it an ideal choice for applications where a combination of moderate strength, ease of fabrication, and affordability is desired.

Understanding 1020 Hot Rolled Steel

To fully appreciate the advantages of 1020 hot rolled steel, it’s important to understand what sets it apart from other types of steel.

Composition and Properties

1020 hot rolled steel is an unalloyed steel with a low carbon content, which gives it good formability and weldability. The low carbon content also makes it more ductile and less hardenable by heat treatment compared to high carbon steels. This grade of steel is known for its ability to undergo significant deformation before fracturing, which is why it’s often used in applications where the steel needs to absorb energy without breaking.

Processing

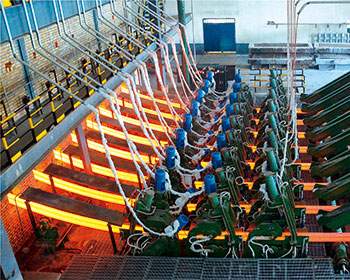

Hot rolled steel is produced by rolling the steel at high temperatures, which gives it a rougher surface finish compared to cold rolled steel. This process also imparts certain mechanical properties that are desirable in many manufacturing applications. The hot rolling process enhances the steel’s toughness and allows for the production of shapes and sections that are not possible with cold rolling.

Cost-Effectiveness

1020 hot rolled steel is relatively inexpensive compared to other specialty steels, making it an attractive option for cost-conscious manufacturers. Its wide availability and the ease of production contribute to its lower cost, allowing manufacturers to achieve economies of scale.

Applications of 1020 Hot Rolled Steel

The versatility of 1020 hot rolled steel makes it suitable for a wide range of applications in various industries.

Automotive Industry

In the automotive industry, 1020 hot rolled steel is used for manufacturing car frames, wheels, and other structural components due to its balance of strength and ductility. The steel’s ability to absorb impact energy without breaking makes it an excellent choice for safety-critical components like car chassis and suspension parts.

Construction

In construction, 1020 hot rolled steel is used for rebar, beams, and other structural elements that require strength and durability while being cost-effective. Its resistance to bending and twisting makes it ideal for reinforcing concrete and contributing to the overall structural integrity of buildings and bridges.

Agricultural Equipment

For agricultural equipment, 1020 hot rolled steel is ideal for its resistance to wear and its ability to withstand the rigors of outdoor use. Its durability and strength make it suitable for components like ploughs, tractor frames, and other heavy machinery that are exposed to harsh conditions.

Furniture and Appliance Manufacturing

In furniture and appliance manufacturing, 1020 hot rolled steel is used for its ease of fabrication and ability to hold complex shapes. Its formability allows for the creation of intricate designs, while its strength ensures the longevity of the finished product.

Advantages of 1020 Hot Rolled Steel

The advantages of 1020 hot rolled steel stem from its unique properties and how they align with manufacturing needs.

Formability

1020 hot rolled steel is easy to bend and shape, making it ideal for manufacturing complex parts that require forming processes. This property is particularly beneficial in industries where parts need to be formed into specific shapes, such as automotive panels or furniture frames.

Weldability

The low carbon content of 1020 hot rolled steel makes it highly weldable, which is essential for many assembly processes in manufacturing. Its ability to be easily joined without the risk of cracking or breaking makes it a popular choice for applications that require welding, such as in the construction of steel structures or the assembly of automotive components.

Machinability

This grade of steel is relatively easy to machine, which can lead to faster production times and lower costs for parts that require machining. The ease of machining also allows for greater design flexibility, as complex features can be incorporated into the final product with relative ease.

Surface Finish

The rough surface finish of hot rolled steel can be advantageous in applications where a better grip is needed, such as in the threads of bolts and screws. This texture can also provide additional resistance to slipping and improve the overall durability of the component.

A Comparative Analysis of 1020 Hot Rolled Steel

To provide a clearer picture of why 1020 hot rolled steel is chosen over other materials, here’s a comparative analysis of its properties:

1020 Hot Rolled Steel Property Table

| Property | Description | Advantage |

|---|---|---|

| Tensile Strength | The ability of the steel to withstand stretching | 1020 HRS has moderate tensile strength, suitable for many applications without the need for high-strength steels. |

| Yield Strength | The point at which steel begins to deform permanently | Offers a good balance of strength and ductility, making it versatile for a range of uses. |

| Hardness | Resistance to surface indentation or abrasion | Its low hardness makes it easy to machine and form. |

| Weldability | Ability to join pieces of metal together by heating | The low carbon content makes 1020 HRS highly weldable, which is beneficial for assembly processes. |

| Machinability | Ease of cutting and shaping the steel | 1020 HRS’s low carbon content contributes to its good machinability, reducing production time and costs. |

This table provides a snapshot of the different properties of 1020 hot rolled steel and how they contribute to its overall advantages in manufacturing applications.

Considerations for Using 1020 Hot Rolled Steel

While 1020 hot rolled steel offers many benefits, there are also considerations to keep in mind when selecting it for manufacturing applications.

Corrosion Resistance

1020 hot rolled steel does not have inherent corrosion resistance, so it may require additional treatments or coatings for applications where rust prevention is important. This can include applications in outdoor environments or in contact with aggressive chemicals.

Hardness and Wear Resistance

For applications requiring high hardness or wear resistance, 1020 hot rolled steel may not be suitable without additional heat treatments or surface modifications. This grade of steel is best suited for applications where moderate wear resistance is sufficient.

Fatigue Resistance

While 1020 HRS has good ductility, its fatigue resistance may be limited compared to higher strength steels, especially in cyclic loading conditions. This should be considered when designing components that will be subjected to repeated stress or strain.

Conclusion

1020 hot rolled steel offers a range of advantages that make it a popular choice in the manufacturing industry. Its formability, weldability, machinability, and cost-effectiveness position it as a versatile material for many applications. By understanding the properties and advantages of 1020 hot rolled steel, manufacturers can make informed decisions about material selection that align with their production needs and cost constraints. Whether for structural components, mechanical parts, or decorative elements, 1020 hot rolled steel provides a reliable and economical solution.

FAQ

Q: What is the main benefit of using 1020 hot rolled steel in manufacturing?

A: The main benefits include its formability, weldability, machinability, and cost-effectiveness, which make it suitable for a wide range of applications. Its balance of strength and ductility also makes it an excellent choice for applications requiring moderate strength and the ability to absorb impact without fracturing.

Q: How does 1020 hot rolled steel compare to other grades of steel in terms of strength?

A: 1020 hot rolled steel has moderate strength and is less hardenable than high carbon steels, making it more suitable for applications where high ductility is required rather than extreme strength. It is often chosen for its balance of properties rather than for applications requiring the highest levels of strength.

Q: Can 1020 hot rolled steel be used in outdoor applications where corrosion resistance is important?

A: While 1020 HRS does not have inherent corrosion resistance, it can be coated or treated to provide protection against rust, making it suitable for outdoor use. Common treatments include galvanizing, painting, or applying other protective coatings to extend its service life in corrosive environments.

Q: Is 1020 hot rolled steel difficult to machine?

A: No, 1020 HRS is relatively easy to machine due to its low carbon content, which contributes to its good machinability. This property allows for faster production times and lower costs for parts that require machining, making it a popular choice for manufacturers looking to optimize their production processes.

Q: What are the typical applications of 1020 hot rolled steel in the automotive industry?

A: In the automotive industry, 1020 hot rolled steel is used for manufacturing car frames, wheels, and other structural components where a balance of strength and ductility is required. It is also used in the production of suspension components, body panels, and other parts that need to withstand stress without breaking.