Q235 Steel Equivalent Grades vs. Global Standards: 5 Critical Risks

Table of Contents

Introduction

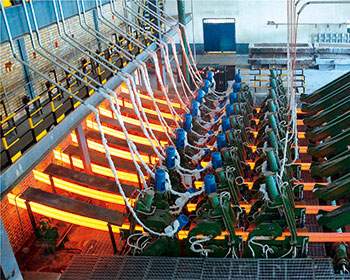

In today’s globalized steel market, understanding Q235 Steel Equivalent Grades and their compatibility with international standards such as ASTM, EN, and JIS is essential for industrial buyers. Q235 steel, a widely used Chinese carbon structural steel, is valued for its balanced strength, weldability, and versatility. Its applications span construction, machinery manufacturing, transportation, and low- to medium-pressure vessel production.

However, substituting Q235 steel for foreign steel grades without thorough evaluation can introduce several critical risks. Differences in mechanical properties, chemical composition, regulatory standards, and supply chain reliability may result in operational failures, safety hazards, or project delays. This article explores these risks in depth, offering guidance for B2B buyers who seek reliable steel sourcing solutions while ensuring project safety and compliance.

Understanding Q235 Steel Equivalent Grades

Q235 steel is classified as a low-carbon structural steel and is widely utilized across industries that demand a careful balance of strength, ductility, and weldability. Its versatility makes it a go-to choice for general structural applications, where reliable mechanical performance at a reasonable cost is critical. The designation “Q235” indicates the minimum yield strength in megapascals (MPa) the steel can withstand under standard testing conditions, reflecting its suitability for moderate-strength engineering projects.

Key Mechanical Properties of Q235 Steel

Understanding the mechanical characteristics of Q235 steel is essential for ensuring it meets project-specific requirements. The key properties include:

- Yield strength: 235 MPa, which indicates the stress at which steel begins to deform plastically.

- Tensile strength: 370–500 MPa, providing resistance against stretching or pulling forces.

- Elongation: ≥20%, ensuring the material can deform sufficiently without fracturing.

- Hardness: 120–180 HB, which balances machinability and wear resistance.

- Chemical composition: ≤0.22% Carbon, 0.30–0.65% Manganese, ≤0.045% Phosphorus, ≤0.045% Sulfur, affecting weldability, ductility, and corrosion resistance.

These properties collectively enable Q235 steel to perform reliably in various applications while allowing for easy fabrication and welding.

Equivalent Grades in Global Standards

Several international steel grades are roughly equivalent to Q235 steel, though minor variations may exist:

- ASTM A36: Widely used in the U.S. for structural steel applications.

- EN S235JR: European standard covering general structural applications.

- JIS SS400: Japanese standard for mild steel utilized in construction and machinery.

Although these grades are considered equivalent in many respects, differences in chemical composition, mechanical performance, and testing procedures can significantly affect certain industrial applications, particularly those requiring high precision or heavy load-bearing capacity.

Major Differences Between Q235 and Global Steel Grades

For B2B buyers and industrial engineers, understanding the nuanced differences between Q235 steel and international equivalents is critical for safe and effective material selection.

Chemical Composition Variance

Slight differences in carbon, manganese, sulfur, and phosphorus content can significantly impact weldability, ductility, and corrosion resistance. For instance, ASTM A36 allows slightly higher carbon content than Q235, which can increase hardness but may reduce flexibility in welded joints. These small chemical differences can determine whether a steel grade is suitable for specific environmental conditions or fabrication methods.

Mechanical Property Deviations

While yield strength and tensile strength may seem comparable on paper, variations in elongation, impact resistance, and fatigue performance can lead to unexpected material failures under extreme conditions. Q235 steel is optimized for moderate-strength applications, whereas ASTM or EN equivalents might be tested for higher stress scenarios, affecting long-term durability in critical engineering projects.

Testing and Certification Standards

International standards often require extensive testing, including tensile, impact, and fatigue assessments. Q235 steel, while meeting Chinese national standards, may not always undergo the same rigorous testing protocols. For projects that demand verified compliance with global engineering standards, this can introduce potential risks.

Corrosion and Surface Finish Differences

Differences in rolling processes, heat treatment, and alloying elements can influence corrosion resistance and surface quality. B2B buyers must consider whether Q235 steel is suitable for outdoor, marine, or chemically aggressive environments, or if additional protective measures like galvanization or coatings are required.

Key Applications of Q235 Steel Equivalent Grades

The versatility and reliability of Q235 steel make it a preferred material across multiple industries:

Construction

Q235 and its equivalents are extensively used in:

- Bridge structures

- Beams, columns, and frameworks

- Reinforced roofing materials

The steel’s combination of tensile strength and ductility ensures structural integrity while enabling relatively easy fabrication and assembly.

Machinery Manufacturing

Equipment frames, housings, and support structures frequently utilize Q235 steel. Its weldability and machinability allow for customized shapes and complex assemblies.

Pressure Vessels and Storage Tanks

While Q235 is suitable for low-to-medium pressure vessels, proper evaluation is necessary when substituting with international equivalents to avoid fatigue failures or leaks.

Transportation Equipment

Vehicle chassis, trailers, and agricultural machinery benefit from Q235’s strength-to-weight ratio, ensuring durability without excessive mass.

Correctly matching the equivalent grade ensures structural integrity and project reliability.

5 Critical Risks When Using Q235 Steel Equivalent Grades

Mechanical Performance Risk

Using an inappropriate equivalent grade can result in unexpected structural failures due to differences in yield strength, tensile strength, or elongation. For example, substituting a slightly lower tensile strength grade in heavy machinery may lead to deformations under load or premature fatigue failure.

Corrosion Resistance Risk

Variations in chemical composition can affect corrosion resistance, especially in harsh environments. Applying coatings or selecting alternative grades may be necessary to prevent premature degradation.

Regulatory Compliance Risk

International projects often mandate steel to meet specific ASTM, EN, or JIS certifications. Misalignment could breach contracts or local building codes, potentially leading to legal liabilities.

Fabrication and Welding Risk

Variations in carbon content or alloying elements can affect weldability. Improper welding may cause cracks, joint failures, or reduced fatigue life.

Supply Chain Risk

Sourcing Q235 steel from unreliable suppliers may result in inconsistent quality, batch variability, or delays, affecting project timelines and reliability.

Comparative Table of Q235 Steel Equivalent Grades

| Property / Standard | Q235 Steel | ASTM A36 | EN S235JR | JIS SS400 | Key Consideration |

|---|---|---|---|---|---|

| Yield Strength (MPa) | 235 | 250 | 235 | 245 | Small differences can impact load-bearing designs |

| Tensile Strength (MPa) | 370–500 | 400–550 | 360–510 | 400–510 | Evaluate for high-stress applications |

| Elongation (%) | ≥20 | ≥20 | ≥20 | ≥20 | Ensures flexibility and formability |

| Carbon Content (%) | ≤0.22 | ≤0.26 | ≤0.20 | ≤0.22 | Affects weldability and hardness |

| Application Scope | General | Structural | Structural | Structural | Consider project-specific requirements |

This table highlights critical differences and considerations for industrial buyers sourcing steel internationally.

Best Practices for Safe Use of Q235 Steel Equivalent Grades

Ensuring the safe and effective use of Q235 steel equivalent grades in industrial projects requires a systematic approach. Following best practices helps minimize risks related to mechanical performance, corrosion, compliance, and supply chain reliability.

Verify Mechanical Specifications

Before procurement, it is critical to cross-check the steel’s mechanical properties, including yield strength, tensile strength, and elongation, against the specific requirements of your project. Evaluating load-bearing capacity ensures that the material can withstand operational stresses without deformation or failure. Additionally, consider fatigue resistance for components subjected to repeated loading, and assess thermal performance if the steel will be used in high- or low-temperature environments. Proper verification reduces the likelihood of structural failures, operational downtime, and costly rework.

Check Supplier Certification

Supplier reliability is a key factor when sourcing Q235 steel equivalent grades. Always request mill test certificates (MTC), chemical composition reports, and compliance documentation. These certificates provide assurance that the steel meets national or international standards, including ASTM, EN, or JIS specifications. Working with certified suppliers also ensures batch-to-batch consistency, which is particularly important for large-scale projects where variations in steel quality can compromise structural integrity and regulatory compliance.

Follow Engineering Standards

Adhering to recognized engineering standards is essential for safe and reliable use. Reference the relevant ASTM, EN, or JIS specifications for mechanical testing procedures, welding techniques, and corrosion resistance requirements. Following these guidelines minimizes risks such as improper welds, material fatigue, and premature corrosion. Integrating standardized testing and fabrication methods into your procurement and manufacturing processes ensures that your project meets global quality and safety benchmarks.

Pilot Testing

Before committing to full-scale procurement, consider conducting small-scale trials or testing sample materials. Pilot testing allows you to assess the steel’s performance under real operational conditions, including load stress, temperature fluctuations, and environmental exposure. This step is particularly important when substituting international equivalents, as minor differences in composition or mechanical properties may affect performance. Successful pilot tests provide confidence that the selected steel will perform reliably across the project lifecycle.

Maintain Traceability

Traceability is critical for quality assurance, regulatory compliance, and risk management. Keep detailed records of batch numbers, chemical composition, mechanical test results, and supplier certifications. Maintaining a traceable audit trail ensures that any issues can be quickly identified and addressed. It also demonstrates due diligence to regulators and clients, supporting compliance with industry standards and contractual obligations. Proper record-keeping is an essential component of a robust steel management system, enhancing both safety and accountability.

Additional Considerations

- Corrosion Protection: Evaluate whether additional surface treatments, such as galvanization or protective coatings, are needed to prevent environmental degradation.

- Storage and Handling: Ensure that steel is stored in controlled environments to prevent contamination, moisture absorption, or mechanical damage before use.

- Regular Inspections: Conduct routine inspections of installed components to monitor for signs of stress, corrosion, or deformation, allowing for timely intervention.

- Training and Documentation: Educate engineering and fabrication teams on proper handling, welding, and installation procedures to maintain material integrity.

By following these best practices, B2B buyers and project managers can mitigate the risks associated with Q235 steel equivalent grades, ensuring safe, reliable, and compliant use in construction, machinery, transportation, and industrial applications.

Conclusion

Q235 Steel Equivalent Grades provide cost-effective and versatile solutions for many industrial applications, but careful evaluation is essential when integrating them with global standards. Differences in chemical composition, mechanical properties, regulatory compliance, and supply chain reliability can introduce significant risks if overlooked. By verifying specifications, consulting engineering standards, conducting pilot testing, and maintaining traceability, B2B buyers can make informed decisions that ensure safety, performance, and compliance. Effective quality control and reliable sourcing are critical for achieving consistent outcomes in projects utilizing Q235 steel or its international equivalents.

FAQ

Q1: Can Q235 steel be directly replaced with ASTM A36?

While similar, direct substitution without evaluation is not recommended due to minor differences in chemical composition and mechanical properties.

Q2: What industries benefit most from Q235 steel?

Construction, machinery manufacturing, transportation equipment, and low-to-medium pressure vessels commonly use Q235 steel.

Q3: How do I verify Q235 steel equivalent grades?

Request mill test certificates, compare mechanical properties, and ensure compliance with relevant international standards.

Q4: Are there corrosion concerns with Q235 steel?

Yes, environmental conditions can affect corrosion resistance. Coatings, galvanization, or alternative grades may be necessary.

Q5: What are the risks of low-quality Q235 steel?

Inconsistent properties, weld failures, and structural safety issues can arise if the supplier is unreliable or quality checks are insufficient.

Q6: How often should mechanical testing be conducted?

Routine testing of each batch is recommended, including tensile and impact tests, especially for structural or load-bearing applications.

Q7: Can modular steel structures use Q235 equivalents safely?

Yes, but only after confirming that mechanical properties and certifications meet design requirements.

Q8: What role does carbon content play in equivalency?

Carbon content directly affects hardness, weldability, and fatigue performance. Differences must be carefully considered in substitution.