What is AISI 1020 Steel? 1 Ultimate Guide

Table of Contents

Introduction

Choosing the correct material for industrial and structural applications is critical, and carbon structural steels are often at the top of the list. Among the most fundamental grades is what is aisi 1020 steel. Understanding this material requires knowledge of the standards bodies that define it and its place within the vast spectrum of ferrous alloys. This ultimate guide explores the fundamental definition of what is aisi 1020 steel, clarifies the naming conventions, and establishes the crucial basis for comparing it with other popular grades like AISI 1018 and AISI 1045, helping engineers and manufacturers select the suitable material for their specific needs.

Understanding the Carbon Steel Naming Convention

The carbon steel naming convention is a systematic method used to identify the type of steel, its carbon content, and its intended application. When looking at a designation like “AISI 1020 Steel,” the structure of the name provides important insights about the material’s properties, making it easier for engineers, manufacturers, and suppliers to quickly understand the steel’s composition and its potential uses.

The AISI component stands for the American Iron and Steel Institute, a professional organization that once played a significant role in setting steel standards in the United States. Although AISI no longer directly sets standards, its naming system continues to be widely recognized and used. Over time, the ASTM (American Society for Testing and Materials) standards have become more prominent in iron and steel specifications, and the naming system under ASTM often follows similar structures. In addition, the Society of Automotive Engineers (SAE) is another important body that helps define steel grades, particularly those used in automotive applications.

Decoding the “AISI 1020 Steel”Designation

The designation “AISI 1020 Steel” is a prime example of how the naming convention works. This naming system, particularly the 4-digit number used in the AISI and SAE designation systems, immediately communicates key information about the steel’s composition and its intended applications. Let’s break it down to better understand each component:

1. The “10” Prefix: Carbon Structural Steel Bar

The first two digits of the designation “10” signify that the steel is a carbon structural steel bar. This category refers to steels primarily composed of carbon, with only small amounts of alloying elements like manganese, silicon, or others, making them suitable for structural uses. The 10XX series refers to a range of carbon steels, specifically those made from carbon alone with little to no additional alloying elements.

- 10XX Series: This series encompasses 49 different grades, each designated with a 4-digit code ranging from 1005 to 1095. The numbers within this range represent different levels of carbon content. As you go up the number sequence, the carbon content of the steel increases, leading to stronger but less ductile steels.

- Structural Steel Bars: These steels are commonly used for structural applications, such as beams, columns, shafts, and other components in engineering structures. They are typically easy to machine and weld, making them versatile for various industries, including automotive and manufacturing.

2. The “20” Suffix: Carbon Content

The last two digits, “20,” provide insight into the carbon content of the steel. Specifically, in the case of AISI 1020, the carbon content is approximately 0.20%. This is what makes it a low-carbon steel.

- Low Carbon Steel: Carbon steels with a carbon content of less than 0.30% are classified as low-carbon steels. Low-carbon steels are typically more ductile, easier to form, and more weldable than higher-carbon steels. However, their lower carbon content means they are not as strong or wear-resistant as high-carbon steels.

- Impact on Properties: The 0.20% carbon content in AISI 1020 gives it a balance of strength and formability, making it suitable for a variety of applications where strength is needed, but ductility and ease of machining are equally important. It’s commonly used in applications like shafts, gears, axles, and other components that require moderate strength.

3. How the Numbering System Helps Differentiate Steel Types

The structure of the 10XX system allows engineers to quickly understand the differences between grades. Here’s how the system breaks down:

- Carbon Content: As noted, the last two digits indicate the carbon content in percentage. For example:

- 1020: 0.20% carbon.

- 1030: 0.30% carbon.

- 1050: 0.50% carbon.

- 1095: 0.95% carbon.

- Steel Series Identification: The initial “10” series indicates that the steel is a carbon steel (as opposed to an alloy steel, which might be denoted by a different prefix like “41XX” for alloy steels). The higher the final number in the sequence (for instance, 1095), the higher the carbon content and the greater the steel’s strength, but at the cost of flexibility and ease of fabrication.

4. Understanding the Impact of Carbon Content

The carbon content in a steel alloy is one of the most important factors in determining its overall properties, such as:

- Strength: Higher carbon content results in higher strength, which is one of the reasons why high-carbon steels like 1095 are used in applications where high strength is critical, such as cutting tools and springs.

- Ductility: As the carbon content decreases, the steel becomes more ductile, meaning it can be bent or shaped more easily. Steel grades like 1020 are commonly used in applications requiring high formability and impact resistance, where strength alone is not sufficient.

- Weldability: Lower-carbon steels are more easily welded than higher-carbon steels. AISI 1020’s low carbon content makes it well-suited for welding applications.

- Hardness: Hardness increases as the carbon content increases. AISI 1020, being a low-carbon steel, has moderate hardness and is less likely to become brittle or suffer from the risks associated with over-hardening, which can occur in higher-carbon steels.

5. Practical Applications of AISI 1020 Steel

AISI 1020 is one of the most widely used low-carbon steels. Its balance of good strength, moderate hardness, and formability makes it an ideal choice for many common applications. Here are some examples of where AISI 1020 steel is used:

- Manufacturing: Components such as shafts, gears, axles, and pistons that require moderate strength and resistance to wear, but also require ease of fabrication, are often made from AISI 1020 steel.

- Machining: AISI 1020’s excellent machinability allows it to be used in various machining processes without causing excessive tool wear.

- Welding: This steel is well-suited for welding applications, such as in the fabrication of structural components for bridges or buildings.

- Automotive Parts: It’s used in producing automotive parts like axles and spindles, where moderate strength and excellent weldability are needed.

6. Comparison of AISI 1020 with Other Carbon Steels

The AISI 1020 steel is a standard in low-carbon steel grades, but how does it compare to other steels in the same series?

- AISI 1018: Slightly lower in carbon content than 1020, AISI 1018 has slightly better weldability and machinability but offers lower strength.

- AISI 1045: This steel has a higher carbon content of around 0.45%, which increases its strength but reduces its weldability and formability compared to 1020.

- AISI 1095: A much higher carbon content (around 0.95%) means this steel is much harder and stronger, but it becomes more brittle and is more difficult to weld and machine.

Core Characteristics of What is AISI 1020 Steel

As a low-carbon steel, what is aisi 1020 steel offers a specific balance of properties. Although the sources do not detail the mechanical properties, the carbon content (approximately 0.20%) determines its general characteristics relative to other grades. Due to its lower carbon percentage, it generally exhibits better formability and weldability compared to higher-carbon structural steels, making it a versatile choice for applications that require ductility rather than extreme hardness.

| Steel Grade | Standard Designation | Approximate Average Carbon Content | General Characteristics (Based on Carbon % Theory) | Typical Usage Focus |

| AISI 1020 | Carbon Structural Steel (10XX) | 0.20% | Good weldability, relatively low strength, high ductility | General fabrication, lower stress parts |

| AISI 1018 | Carbon Structural Steel (10XX) | Typically around 0.18% (Similar to 1020) | Excellent machinability, good balance of toughness and strength | Machined parts, cold forming |

| AISI 1045 | Carbon Structural Steel (10XX) | 0.45% | Higher strength and hardness than 1020, suitable for high-strength parts | Axles, shafts, gears, high-strength machine parts |

| AISI 4140 | Alloy Structural Steel (41XX) | 0.40% (Cr-Mo Alloy) | High strength, excellent toughness, requiring heat treatment | Manufacturing high-strength mechanical parts |

What is AISI 1020 Steel? Comparing 1020, 1018, and 1045

The primary difference between common 10XX carbon structural steels lies in their average carbon content, which directly The world of carbon steels can be complex, with a wide variety of grades tailored to different applications based on their composition, properties, and manufacturing requirements. One of the most common classifications for carbon steel is based on the 10XX series (e.g., AISI 1020, 1018, and 1045). These grades are part of the American Iron and Steel Institute (AISI) system, where the numbers indicate the carbon content and, in many cases, provide a direct insight into the material’s performance characteristics.

Decoding the Carbon Content and Mechanical Properties

The fundamental difference between these grades lies in the carbon content. Carbon content plays a crucial role in determining the strength, hardness, weldability, formability, and machinability of the steel. Let’s take a deeper look at how AISI 1020, 1018, and 1045 compare, specifically focusing on how their carbon content impacts their suitability for different applications.

1. AISI 1020 Steel – 0.20% Carbon

AISI 1020 Steel is a low-carbon steel with an average carbon content of approximately 0.20%. This low carbon content gives the material excellent formability and weldability, making it ideal for applications that require easy fabrication without the need for very high strength.

- Strength and Hardness: Due to its low carbon content, AISI 1020 has moderate strength and hardness. It is significantly more ductile than higher-carbon steels, allowing it to be easily shaped, bent, and welded. However, it is not as strong or wear-resistant as steels with higher carbon content.

- Common Uses: AISI 1020 is commonly used in parts that require good machinability and formability but do not need to withstand heavy wear. Applications include shafts, gears, axles, and pistons, particularly in situations where strength is less of a concern and ease of processing is more important.

2. AISI 1018 Steel – 0.18% Carbon

AISI 1018 Steel is another low-carbon steel, slightly lower in carbon content than AISI 1020, typically ranging around 0.18% carbon. It shares many similarities with AISI 1020 but differs in certain minor properties that might make it more suitable for specific applications.

- Machinability: AISI 1018 is often noted for its excellent machinability, making it ideal for manufacturing processes where parts need to be machined to precise dimensions with minimal effort. The slight reduction in carbon content compared to AISI 1020 can make it slightly easier to machine in some cases, but the overall mechanical properties are still quite similar.

- Forming and Welding: Both AISI 1018 and 1020 are easily welded and formed. However, AISI 1020 may have a slight advantage in terms of forming, as the slightly higher carbon content in AISI 1018 could affect its bendability in certain circumstances.

- Common Uses: Like AISI 1020, AISI 1018 is also used in applications requiring good machinability and formability, including machined parts, automotive components, and fasteners.

3. AISI 1045 Steel – 0.45% Carbon

AISI 1045 Steel is a medium-carbon steel with an average carbon content of 0.45%. This higher carbon content significantly increases the strength and hardness of the material, making it suitable for applications that require greater load-bearing capacity and resistance to wear.

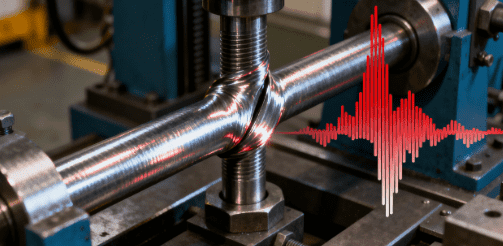

- Strength and Hardness: Due to its higher carbon content, AISI 1045 is much stronger and harder than AISI 1020 and 1018. However, this comes at the cost of formability and weldability, as higher-carbon steels can be more difficult to machine, weld, and form.

- Applications: AISI 1045 is often used in applications where strength and wear resistance are more critical, such as in high-stress mechanical components like shafts, gears, spindles, and tooling. These components often require heat treatment processes like quenching or tempering to maximize strength and durability.

- Comparison to 1020 and 1018: While AISI 1020 and 1018 are favored for their ease of fabrication and good formability, 1045 is selected when higher strength and resistance to wear are necessary. In high-performance machinery or automotive applications, where parts must endure heavy loads or friction, 1045 steel is the material of choice.

AISI 1020 Steel vs. AISI 1045 Steel: The Key Differences

The comparison between AISI 1020 and 1045 Steel is significant because the latter has more than double the carbon content of the former. This difference in carbon content directly influences the mechanical properties of the steel and makes AISI 1045 suitable for applications that require enhanced strength and hardness.

- Strength and Hardness: With 0.45% carbon, 1045 exhibits superior strength and hardness compared to 1020’s 0.20% carbon. AISI 1045’s increased strength makes it ideal for high-strength mechanical parts, such as gears, spindles, and shafts, where mechanical performance under load is essential.

- Machinability and Formability: On the other hand, AISI 1020 is far more formable and easier to machine. This makes it the better choice for applications where parts need to be shaped or welded easily, but extreme strength is not a requirement.

- Cost-Effectiveness: AISI 1020 is generally more cost-effective than AISI 1045, particularly when strength and wear resistance are not primary concerns. It offers a more economical solution for applications that prioritize ease of manufacturing and affordability.

AISI 1020 Steel vs. AISI 1018 Steel: The Minor Differences

While AISI 1020 and AISI 1018 are both low-carbon steels, they differ slightly in terms of composition and properties. The main difference between these two materials is the manganese content, which can slightly affect their machinability and forming properties.

- Machinability: AISI 1018 has a slightly higher manganese content, which can give it better machinability compared to AISI 1020. This can be an advantage in precision machining processes where fine tolerances are required.

- Formability: AISI 1020 may have slightly better formability, especially for applications that involve significant bending or shaping, due to its marginally lower carbon content and corresponding increased ductility.

- Welding: Both grades are weldable, but AISI 1020 may be a better choice for welding operations, as its lower carbon content helps reduce the likelihood of cracking during the welding process.

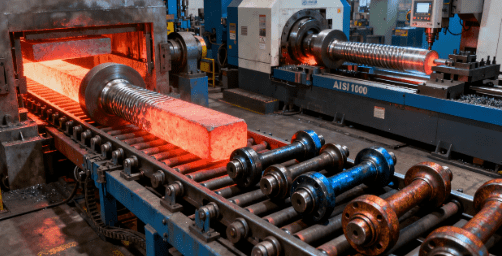

Available Product Forms and Standards

Regardless of whether a material is carbon steel like AISI 1020, a high-manganese carbon steel like AISI 1524, or an alloy structural steel like AISI 4140, these materials are processed and supplied in various forms depending on the needs of the application.

Some of the most common forms of carbon steel products include:

- Round Bar: Used for machining or forming into parts like shafts, axles, and gears.

- Square Bar: Ideal for structural applications or machining.

- Bright Steel Bar: A high-quality product with a smooth finish, used in precision applications.

- Steel Billet: Semi-finished material used for further processing into other steel products.

Conclusion

What is aisi 1020 steel is defined fundamentally by its composition: a carbon structural steel with approximately $0.20%$ carbon content, as defined by the AISI/SAE system and utilized within ASTM standards. Its position as a low-carbon grade dictates its primary advantages—namely, superior workability and weldability—making it an essential material in general engineering applications. When selecting between what is aisi 1020 steel, $1018$, and $1045$, the key determining factor is the carbon percentage and the resulting strength requirement of the final mechanical component. For applications demanding high strength (like manufacturing high-strength mechanical parts), higher carbon or alloy steels are preferable.

FAQ

What is AISI 1020 Steel?

AISI 1020 Steel is a low-carbon steel alloy with an approximate carbon content of 0.20%. It is widely used in manufacturing due to its excellent weldability and machinability. Although it has lower strength compared to higher-carbon steels, its versatility makes it ideal for many general-purpose applications, including structural components and low-stress parts.

What is the difference between AISI 1020 and AISI 1018?

AISI 1018 is a low-carbon steel with a carbon content of around 0.18%, which is slightly less than AISI 1020’s 0.20%. Both steels are similar, but AISI 1018 generally offers better machinability due to slightly higher manganese content. However, AISI 1020 may perform better in applications requiring slightly better forming properties.

Is AISI 1020 Steel heat treatable?

Yes, AISI 1020 steel can be heat-treated. While it has relatively low carbon content, processes like carburizing can be used to enhance its surface hardness. However, its overall strength cannot match that of higher-carbon steels such as 1045 or 4140.

How Does the AISI System Relate to ASTM?

The American standards system involves multiple organizations, including AISI, SAE, and ASTM. While AISI helps set standards, ASTM is the body whose standards are most widely used for iron and steel, incorporating consensus from various industry parties. The designation for structural steel grades, including what is aisi 1020 steel, usually follows the guidelines set out by the SAE system, which is referenced in ASTM standards like ASTM A29/A29M.

What is AISI 1020 Steel Used For?

What is aisi 1020 steel is a general-purpose, low-carbon steel. Based on its low carbon content (approx. 0.20%), it is known for its excellent weldability and machinability, though it possesses lower strength compared to higher-carbon alloys (like $1045$ or $4140$). It is commonly selected for structural components, general fabrication, and low-stress parts where surface hardness can be enhanced through processes like carburization.