Steel Rod: 7 Common Mistakes in Choosing Hardness

Table of Contents

Introduction

When it comes to selecting steel rods for manufacturing, construction, or heavy-duty applications, one of the most critical factors to consider is the hardness of the steel rod. Steel rod hardness directly influences the durability, performance, and longevity of the material. Unfortunately, many B2B buyers make common mistakes when choosing the correct steel rod hardness, which can lead to premature wear, project delays, and unnecessary costs. This blog will explore these mistakes and provide valuable insights into how to make the right decision when selecting the hardness of steel rods.

Mistake #1: Ignoring Material Compatibility in Steel Rod Hardness

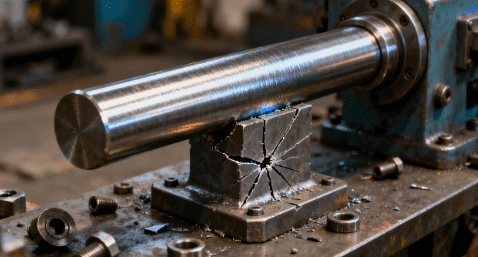

One of the most common mistakes buyers make is choosing steel rods with a hardness level that does not match the material’s intended application. For instance, using a steel rod with high hardness for a project that requires flexibility or impact resistance can cause material failure under stress. Conversely, a steel rod with too low of a hardness for heavy load-bearing tasks may wear out quickly or fail to withstand the pressures it’s subjected to.

Key Considerations

- Ensure compatibility between the steel rod’s hardness and the environment it will operate in.

- Choose steel rods with hardness levels that align with the specific demands of the end-use, such as corrosion resistance or wear resistance.

Mistake #2: Overestimating the Hardness Requirement for Steel Rods

Many buyers tend to overestimate the necessary hardness of a steel rod, thinking that higher hardness means better performance. However, while hardness is important, excessively hard steel rods can actually lead to brittleness and increased risk of failure, especially under impact. Over-hardened steel rods may also present difficulties in machining and processing.

Key Considerations

- Balance between hardness and ductility is crucial.

- Understand that in some applications, a slightly lower hardness could be more beneficial, depending on factors like stress, impact, and the presence of other forces.

Mistake #3: Failing to Account for Environmental Conditions in Steel Rod Hardness

Environmental factors such as temperature fluctuations, moisture, and exposure to corrosive agents can significantly affect the performance of steel rods. When choosing a steel rod, it’s essential to consider these external conditions. For example, steel rods used in high-temperature environments need to have a specific hardness level that allows them to maintain their strength and resist deformation.

Key Considerations

- Select steel rods based on the operational environment (high or low temperatures, exposure to moisture, etc.).

- Ensure that the hardness of the steel rod does not cause corrosion or excessive wear in certain conditions.

Mistake #4: Not Considering the Steel Rod’s End Use

Each application for steel rods has different hardness requirements. The hardness needed for a steel rod used in construction might differ greatly from that of a steel rod used in automotive manufacturing or heavy machinery. Not understanding the exact requirements for the steel rod’s end use can result in performance issues.

Key Considerations

- Define the specific use case before selecting the hardness level.

- Understand how hardness affects the performance, longevity, and safety of the final product.

Mistake #5: Neglecting to Consider Steel Alloy Composition

The composition of the steel alloy plays a significant role in determining the steel rod’s hardness. Different alloys exhibit different hardness characteristics, which is why buyers should consider the material’s chemical makeup and mechanical properties when choosing steel rods for a project. Neglecting alloy composition can lead to selecting a steel rod that does not meet the required strength or durability standards.

Key Considerations

- Choose the right alloy for the desired hardness.

- Consider how the alloy affects the rod’s ability to resist wear, corrosion, or high stress.

Steel Rod Hardness Testing: A Key Step in Preventing Mistakes

Before finalizing the steel rod selection, conducting thorough hardness testing is essential to avoid making these mistakes. There are various hardness testing methods available, including Rockwell, Brinell, and Vickers hardness tests, each suited for different types of steel rods.

Steel Rod Hardness Testing Methods

| Testing Method | Description | Suitable For |

|---|---|---|

| Rockwell | A quick and widely-used method for measuring the hardness of steel rods | Ideal for large-scale production and bulk testing |

| Brinell | Measures hardness by pressing a hardened steel ball into the surface of the material | Suitable for testing rough, uneven surfaces |

| Vickers | Uses a diamond pyramid to measure hardness, offering detailed results | Best for small steel rods or applications requiring high precision |

These tests are essential for ensuring that the steel rod meets the required hardness for its intended application and can withstand the environmental and mechanical stresses it will face.

Mistake #6: Misunderstanding Industry Hardness Standards

Each industry has specific hardness standards that define the acceptable ranges for steel rods based on their application. For example, ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization) provide detailed standards for hardness testing and the mechanical properties of steel rods. Not understanding these standards can lead to purchasing steel rods that do not meet industry expectations, which could cause significant operational issues.

Key Considerations

- Familiarize yourself with industry-specific hardness standards.

- Ensure the steel rods purchased adhere to the relevant standards for your project’s compliance and safety requirements.

Mistake #7: Failing to Account for Long-Term Wear and Tear

Hardness is often assessed as a short-term property, but in many applications, the long-term durability of the steel rod is far more important. Steel rods that appear to have suitable hardness levels may degrade over time, especially under repeated stress, abrasion, and exposure to varying temperatures. Buyers often overlook the importance of understanding the long-term behavior of the material, leading to premature failures.

Key Considerations

- Understand how the steel rod will perform over time under constant or varying stress.

- Account for long-term wear and corrosion resistance when selecting the right hardness.

Steel Rod Hardness Testing: A Key Step in Preventing Mistakes

Before purchasing steel rods, conducting hardness testing is crucial to ensure they meet the required specifications for the intended application. Hardness directly affects a steel rod’s performance, durability, and ability to withstand stress, wear, and load. Without proper testing, you risk selecting an unsuitable material, which could lead to failure, safety hazards, and expensive repairs.

Why Hardness Testing is Important

- Ensures Material Suitability:

Hardness testing helps determine if a steel rod is appropriate for its application. For instance, harder rods may be required for high-load applications, while softer rods may be better for impact resistance. - Prevents Failures:

Incorrect hardness can lead to material failure. Too soft a rod may wear out quickly, while too hard a rod could become brittle and crack under stress. - Quality Assurance:

Manufacturers often perform hardness testing as part of their quality control process. By verifying hardness, you ensure that the steel rods will meet performance and safety standards. - Reduces Costs:

By testing hardness, you avoid costly material failures, repairs, and downtime associated with poor material selection.

Common Steel Rod Hardness Testing Methods

There are three main methods used to measure hardness: Rockwell, Brinell, and Vickers. Each test is suited for different types of materials and applications.

1. Rockwell Hardness Test

The Rockwell test is fast and commonly used, measuring the depth of indentation made by a diamond or steel ball under a specific load. It’s ideal for larger steel rods and bulk testing.

Advantages:

- Quick and reliable.

- Suitable for large-scale production.

Disadvantages: - Less precise for very hard or soft materials.

Best For:

General-purpose applications, such as in construction or automotive industries.

2. Brinell Hardness Test

The Brinell test uses a steel or carbide ball pressed into the material’s surface. The size of the indentation is measured to calculate hardness, making it ideal for rough surfaces.

Advantages:

- Works well with coarse or uneven surfaces.

- Good for thicker materials.

Disadvantages: - Leaves permanent indentations.

Best For:

Heavy machinery and construction, where materials are thick or rough.

3. Vickers Hardness Test

The Vickers test uses a diamond pyramid indenter to make a precise indentation on the material’s surface. It’s ideal for high-precision applications.

Advantages:

- Provides precise measurements, even for small or thin materials.

Disadvantages: - Requires more time and expertise.

Best For:

Applications requiring high accuracy, such as aerospace or electronics.

Selecting the Right Hardness Test

Choosing the appropriate method depends on factors like material size, surface condition, and precision needed:

- Rockwell is ideal for bulk or large-scale testing.

- Brinell works well for materials with rough surfaces.

- Vickers is best for high-precision needs, especially for small or thin rods.

Conclusion

Choosing the right hardness for steel rods is a delicate balancing act. Understanding the material’s environment, application, and the nuances of steel alloy composition are crucial factors in avoiding the common mistakes that could lead to project delays and increased costs. By being mindful of these seven common mistakes, you can ensure that the steel rods you select will provide the durability, strength, and performance needed for your specific applications. Always test the material’s hardness, follow industry standards, and don’t overlook long-term wear potential.

FAQ

1. How do I determine the correct hardness for my steel rods?

The correct hardness is determined by understanding the application’s needs, including the load it will carry, environmental conditions, and industry standards. Consider the balance between hardness, toughness, and flexibility.

2. What is the most accurate method for measuring steel rod hardness?

The Vickers hardness test is the most accurate, particularly for small rods or high-precision applications. However, the Rockwell test is often used for bulk testing due to its speed and reliability.

3. Can I choose a steel rod with excessive hardness?

Yes, over-hardening can result in brittleness, which makes the steel rod more likely to break under impact. Always choose a hardness level that balances durability and flexibility.

4. Why is alloy composition important in choosing steel rod hardness?

The composition of the alloy affects the steel rod’s hardness, strength, and wear resistance. Carbon steel, for example, offers good hardness but may lack ductility, while stainless steel is more resistant to corrosion.

5. How often should steel rods undergo hardness testing?

Steel rods should be tested before purchase and periodically throughout their use, especially in critical applications. Regular testing ensures that the rods maintain the required hardness and performance standards.

6. What industries require specific steel rod hardness standards?

Industries like construction, automotive, aerospace, and heavy machinery often have strict standards for steel rod hardness. Adhering to these standards ensures safety, compliance, and optimal performance.