Steel 42CrMo4: A Comprehensive Guide for Engineers

Introduction

Steel 42CrMo4 is a high-quality alloy steel known for its exceptional strength, toughness, and wear resistance. Widely used in various engineering applications, this steel grade is particularly favored in the automotive, aerospace, and machinery sectors due to its ability to withstand high stress and fatigue. This comprehensive guide will delve into the properties, advantages, applications, and considerations surrounding steel 42CrMo4, providing engineers with the knowledge necessary to make informed decisions when selecting materials for their projects.

Chemical Composition and Properties of 42CrMo4 Steel

The chemical composition of 42CrMo4 steel typically includes carbon (0.38-0.45%), manganese (0.60-0.90%), chromium (0.90-1.20%), molybdenum (0.15-0.30%), and silicon (0.10-0.25%) . These elements work together to provide the steel with its unique properties.

Key Properties of 42CrMo4 Steel

High Tensile Strength: The steel grade known as 42CrMo4 has the potential to demonstrate an impressive tensile strength range, which typically falls between 900 MPa and 1100 MPa, particularly following an appropriate heat treatment process. This heat treatment significantly enhances the mechanical properties of the steel, allowing it to achieve such elevated levels of tensile strength.

Good Toughness: The incorporation of chromium and molybdenum into the steel composition significantly improves its toughness. This enhancement makes the material much more resilient, allowing it to withstand cracking and other forms of damage when subjected to various types of stress.

Excellent Wear Resistance: The alloying elements also contribute to the steel’s ability to withstand wear, making it suitable for components in high-wear environments.

Applications of 42CrMo4 Steel

The versatility of 42CrMo4 steel spans across a wide array of industries, reflecting its unique properties. This material is particularly valued in sectors that require high strength and remarkable durability, which are essential prerequisites for the demanding applications it serves.

Common Applications

Automotive and Aerospace: Used for critical components like axle shafts, steering knuckles, and gears due to its high fatigue strength and impact resistance .

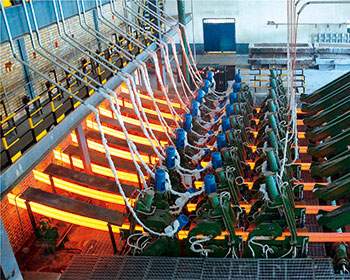

Engineering Machinery: Employed in manufacturing machinery components such as hydraulic cylinders, piston rods, and connecting rods.

Energy Sector: Utilized in components like turbine shafts, generator shafts, and rotor bolts, benefiting from the steel’s ability to withstand high rotational speeds and heavy loads.

Toolmaking: Used in making molds, dies, and cutting tools where durability and precision are critical.

Construction and Mining: Equipment such as crane shafts, drill rods, and excavator pins rely on the toughness and abrasion resistance of 42CrMo4 steel.

Mechanical Properties of 42CrMo4 Steel

The mechanical properties of 42CrMo4 steel are tailored through heat treatment processes such as quenching and tempering . The table below outlines the mechanical properties of 42CrMo4 steel in its hardened and tempered condition:

Mechanical Properties Table

| Diameter Range (mm) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Impact Energy (J) |

|---|---|---|---|---|

| Up to 16 | 1100-1300 | 900 | 10 | 40 |

| 16 to 40 | 1000-1200 | 750 | 11 | 35 |

| 40 to 80 | 900-1100 | 650 | 12 | 35 |

Note: These values are approximate and can vary depending on the specific heat treatment process .

Processing and Machinability of 42CrMo4 Steel

While 42CrMo4 steel offers excellent mechanical properties, its machinability can be challenging, especially in its hardened and tempered condition . The use of carbide tools and appropriate cutting parameters is recommended for optimal results.

Machinability Considerations

- Annealed State: In its annealed state, 42CrMo4 steel can be machined relatively easily.

- Hardened and Tempered State: Machining becomes more difficult due to the high hardness of the steel.

Heat Treatment of 42CrMo4 Steel

Heat treatment plays a crucial role in achieving the desired mechanical properties of 42CrMo4 steel. Common heat treatment processes include:

- Quenching: Rapid cooling in oil or water to achieve high hardness.

- Tempering: Heating to a specific temperature to reduce brittleness and improve toughness.

Heat Treatment Table

| Temperature (°C) | Process | Hardness (HRC) |

|---|---|---|

| 850 | Quenching in oil | 57-59 |

| 200-700 | Tempering | 27-57 |

Conclusion

42CrMo4 steel is a high-strength, durable, and wear-resistant material that is ideal for a wide range of engineering applications. Its ability to withstand high static and dynamic loads, combined with its excellent heat treatment capabilities, makes it a preferred choice for critical components in various industries. Understanding the properties and processing of 42CrMo4 steel is essential for engineers to specify this material effectively in their designs.

FAQ

Q: What are the key properties of 42CrMo4 steel?

A: 42CrMo4 steel is known for its high tensile strength, good toughness, and excellent wear resistance, which make it suitable for heavy-duty machinery components and high-stress applications .

Q: What are the common applications of 42CrMo4 steel?

A: Common applications include automotive and aerospace components, engineering machinery, energy sector components, toolmaking, and construction and mining equipment .

Q: How does the heat treatment process affect the properties of 42CrMo4 steel?

A: Heat treatment, including quenching and tempering, enhances the mechanical properties of 42CrMo4 steel, offering improved hardness and toughness .

Q: What are the considerations for machining 42CrMo4 steel?

A: Machining 42CrMo4 steel can be challenging, especially in its hardened and tempered condition. The use of carbide tools and appropriate cutting parameters is recommended .