Avoid These 5 Cheap Steel Sheets Traps

Table of Contents

Introduction

Steel sheets are essential in numerous industries, from construction and automotive manufacturing to home DIY projects and appliance fabrication. As demand grows, so does the interest in sourcing affordable materials—making cheap steel sheets an attractive option for many buyers. However, while low pricing can offer initial savings, there are several traps hidden beneath the surface that can lead to long-term losses, safety risks, and compromised project quality.

In this blog, we will take a deep dive into the five most common traps associated with cheap steel sheets. Whether you’re a purchasing manager, builder, or independent fabricator, understanding these traps can help you make informed decisions. We’ll also provide useful tips, insights, and a comparison table to help you identify what to look out for when evaluating suppliers and products.

Let’s begin with the first common trap.

Trap 1: Low Quality Coating and Finish on Cheap Steel Sheets

One of the most overlooked issues when purchasing cheap steel sheets is the quality of their coating or finish. Many sheets are promoted as being galvanized or treated with anti-rust solutions, but closer inspection often reveals inconsistencies, uneven application, or substandard protective layers.

Why Coating Matters

Steel is susceptible to corrosion and oxidation when exposed to moisture or certain chemicals. A proper coating significantly increases the durability of the product. With cheap steel sheets, however, manufacturers often cut corners by using thinner layers of zinc or skipping the coating process altogether.

How to Spot the Trap

- Look for inconsistencies in color or surface sheen.

- Test for coating thickness using a gauge if possible.

- Check whether the product meets common standards like ASTM or JIS.

Long-Term Impact

Using inadequately coated cheap steel sheets may result in:

- Accelerated rusting

- Structural weaknesses

- Repeated replacements that increase total cost

Trap 2: Inaccurate Thickness or Misleading Specifications

When buyers opt for cheap steel sheets, one common trap is receiving material that doesn’t meet the advertised thickness or strength. This discrepancy is especially dangerous in applications requiring structural integrity.

Common Specification Issues

- Nominal vs. actual thickness mismatches

- Lower-than-listed tensile strength

- Use of substandard raw materials in sheet production

Practical Example

You may be quoted for 1.2mm thick sheets, only to find upon delivery that the sheets measure just 1.0mm or even 0.9mm. This difference can have significant implications on load-bearing capacity and lifespan.

How to Protect Yourself

- Always ask for mill test certificates (MTCs)

- Use a micrometer to verify thickness on delivery

- Work with suppliers who provide samples and transparency

Trap 3: Inconsistent Sizing and Surface Defects

Uniformity in size and surface condition is essential in any project. Cheap steel sheets often suffer from inconsistent dimensions, warping, or manufacturing defects like pitting and cracks. This trap can add time, cost, and labor to your fabrication or assembly process.

Common Surface Issues

- Waviness and dents

- Roll marks or scratches

- Residual oils or industrial debris

Why This Matters

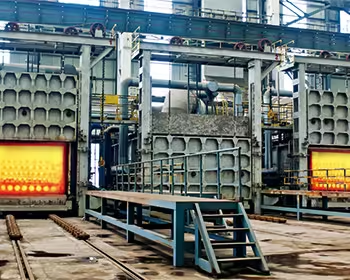

If you are working with automated fabrication systems or laser cutters, inconsistent sizing can result in faulty products or require rework. Additionally, visible surface defects reduce aesthetic appeal and can signal underlying quality control issues at the production plant.

What to Do

- Inspect a sample batch before large orders

- Set up quality assurance checks upon delivery

- Avoid deals that do not include a warranty or return policy

Trap 4: Lack of Certification and Traceability

Traceability and certification ensure that cheap steel sheets come from credible sources with controlled manufacturing processes. Unfortunately, many suppliers of low-cost materials either cannot provide documentation or present fake certificates.

Why Certification Is Critical

Proper certification guarantees that your steel sheets comply with recognized international standards. These include:

- ISO 9001 for quality management

- ASTM standards for mechanical properties

- RoHS or REACH for environmental compliance

The Risk of Non-Certified Steel

- Regulatory compliance failures

- Difficulty in insurance or inspection processes

- Potential legal liabilities for structural failure

What You Can Do

- Demand full traceability from mine to mill

- Cross-check certifications with issuing bodies

- Choose suppliers with visible quality management systems

Trap 5: Hidden Costs in Logistics and Delays

The final trap is not in the steel sheets themselves but in their procurement. Some suppliers lure buyers with low per-unit costs but introduce hidden fees during shipping, taxes, or handling.

Common Hidden Costs

- Extra fees for packaging or palletization

- Long customs clearance times due to incomplete documentation

- Higher-than-quoted shipping rates

Time Delays

Cheap steel sheets often come from far-off or lesser-known suppliers who may not prioritize prompt delivery. Project timelines can be severely impacted by:

- Miscommunication with shipping agents

- Port congestion

- Non-compliance with local import laws

Proactive Solutions

- Ask for an all-inclusive quote

- Verify lead time guarantees

- Choose suppliers with international logistics experience

Comparison Table: Cheap Steel Sheets Trap Indicators

To help you avoid these pitfalls, here is a table summarizing the key indicators of potential traps in cheap steel sheets:

| Trap Type | Red Flags to Watch For | Preventive Action |

|---|---|---|

| Poor Coating | Discoloration, uneven shine, early rust | Check coating thickness, demand specs |

| Inaccurate Specifications | Thinner than promised, weak strength | Use thickness gauge, request MTC |

| Surface and Size Defects | Dents, cracks, warping, irregular sizes | Visual checks, sample before bulk orders |

| No Certification | No MTC, missing ISO or ASTM standards | Confirm traceability, verify certificates |

| Hidden Logistic Costs | Unexpected fees, late delivery, vague terms | Insist on clear quotes, check supplier reviews |

This table serves as a practical checklist during your supplier evaluation process.

How to Find Reliable Cheap Steel Sheets Without Falling for Traps

While this article has emphasized the potential risks of buying cheap steel sheets, it’s important to note that affordable options aren’t always synonymous with poor quality. In many cases, buyers can secure excellent deals—so long as the sourcing strategy is well-informed and carefully executed.

The goal is to strike the right balance between price and performance. Don’t fall into the trap of focusing solely on cost. Instead, evaluate every aspect of your purchase, from supplier reputation to product testing, shipping terms, and long-term usability. Here’s how to make smart purchasing decisions.

Tips to Buy Wisely

1. Source from Verified Suppliers

Always prioritize sourcing cheap steel sheets from verified or pre-vetted manufacturers. Use platforms like Alibaba Gold Suppliers, Made-in-China Audited Suppliers, or regional procurement directories that include factory audits, certifications, and customer reviews. You may also consider working with trusted sourcing agents who have a background in metallurgy or industrial procurement.

A verified supplier not only reduces the risk of receiving substandard products but also typically offers better communication, post-sale support, and a more transparent pricing structure.

2. Negotiate Sample Orders

Before committing to bulk purchases, request sample sheets. This allows you to physically inspect the material’s finish, thickness, flexibility, and coating. It’s also a great opportunity to verify if the supplier’s product description matches the reality.

Don’t just rely on appearance—perform basic mechanical testing if possible. Even a small trial run in your production line can reveal issues with tolerances, workability, or compatibility.

3. Perform On-Site Inspections

If you’re planning to order large quantities, especially for industrial or infrastructure use, it’s well worth investing in on-site inspections. Many third-party quality control firms offer inspection packages tailored for steel products. These inspections typically include:

- Visual and dimensional checks

- Surface and edge finish assessments

- Verification of labeling and packaging

- Material certificate validation (like MTC, COA, or RoHS compliance)

A single on-site inspection can prevent serious losses and confirm that your cheap steel sheets are indeed fit for purpose.

4. Establish SLAs (Service Level Agreements)

A Service Level Agreement (SLA) outlines the expectations and responsibilities between you and the supplier. This includes agreed delivery timelines, product specifications, packaging standards, and acceptable defect rates.

An SLA protects your purchase and gives you a legal foundation for negotiation or dispute resolution if the supplier fails to meet agreed standards. Even if the supplier is overseas, having documented terms can influence their behavior and increase accountability.

5. Review Feedback and Company Background

Before placing any order, research the supplier’s track record. Look for:

- Years in business

- Repeat customers

- Verified transactions

- Detailed reviews on B2B platforms or forums

A reliable supplier will often have case studies, testimonials, or online presence indicating stable operations. Avoid companies with no digital footprint, unverifiable addresses, or untraceable email domains.

6. Understand the Total Cost of Ownership

Even when the upfront cost of cheap steel sheets seems attractive, remember to evaluate the total cost of ownership (TCO). This includes:

- Shipping and customs fees

- Storage and handling costs

- Rework or scrap due to poor quality

- Maintenance or replacement frequency

Sometimes, slightly more expensive steel sheets with consistent quality can offer better value over the long term.

7. Ask for Clear Documentation

Always ensure the supplier provides complete documentation with every shipment, including:

- Mill Test Certificates (MTCs)

- Packing lists

- Commercial invoices

- Certificates of Origin

- Safety data sheets, if relevant

Lack of documentation is often a red flag and could delay customs clearance or regulatory approvals.

When Done Right, It’s a Smart Investment

Finding reliable cheap steel sheets is not just about saving money—it’s about building a sustainable procurement system that supports your business needs without compromise. With due diligence, strategic negotiation, and clear communication, you can unlock excellent deals while avoiding the common pitfalls we’ve discussed earlier in this article.

Whether you’re sourcing for construction, fabrication, or resale, following these steps can help you transform a risky purchase into a reliable, cost-effective supply chain advantage.

Conclusion

Buying cheap steel sheets can be a strategic move for businesses and individuals alike—but only when approached with due diligence. From poor coatings and inaccurate specs to shady certifications and logistical mishaps, the traps are real and often costly.

This guide has armed you with practical knowledge to help you identify and avoid the five most common traps. Remember that low price doesn’t have to mean low quality if you know what to watch for. By following our checklist and recommendations, you can safely navigate the world of affordable steel and make smart, sustainable purchasing decisions.

FAQ

What are cheap steel sheets typically used for?

Cheap steel sheets are often used in non-structural applications like ducting, enclosures, automotive parts, and interior construction. However, it’s important to ensure they meet strength and quality requirements for each specific use.

Are cheap steel sheets always lower in quality?

Not always. Some manufacturers offer lower prices due to economies of scale or regional advantages. The key is verifying quality through samples, certificates, and testing.

How do I verify the actual thickness of cheap steel sheets?

Use a calibrated micrometer or thickness gauge on several spots across the sheet. Always check against the promised dimensions in the order.

What certifications should I look for when buying cheap steel sheets?

Look for ISO 9001, ASTM standards, and any region-specific certifications related to strength, safety, and environmental impact.

Can I return low-quality cheap steel sheets?

That depends on the supplier’s return policy. Always clarify warranty terms before purchase and keep all documentation to support any return claim.