5 Key Properties of 40Mn2 Steel You Should Know

Table of Contents

Introduction

When it comes to selecting high-performance steel for industrial applications, 40Mn2 steel stands out as a popular choice. Known for its versatility and strength, 40Mn2 steel is used in various sectors, from automotive manufacturing to heavy machinery production. This blog will dive into the five key properties of 40Mn2 steel that make it an ideal material for demanding applications. Understanding these properties will help manufacturers and engineers make informed decisions when selecting materials for their projects.

What is 40Mn2 Steel?

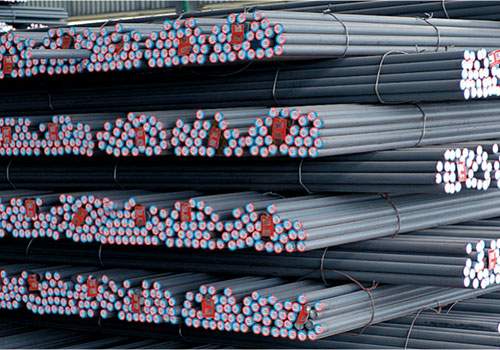

40Mn2 steel is a medium-carbon alloy steel that contains manganese and other elements. Its chemical composition allows it to exhibit a combination of strength, toughness, and ductility. The “40” refers to the carbon content of approximately 0.40%, while “Mn2” indicates the presence of manganese. This steel grade is often used for parts that require high strength and resistance to wear and impact.

1. High Strength-to-Weight Ratio

One of the key properties that make 40Mn2 steel highly desirable is its impressive strength-to-weight ratio. It offers exceptional tensile strength without compromising on weight, making it ideal for applications where both strength and weight are critical considerations.

Why Strength-to-Weight Ratio Matters

For industries such as automotive, aerospace, and manufacturing, optimizing weight while maintaining strength is a constant challenge. A higher strength-to-weight ratio means that parts made from 40Mn2 steel can carry heavier loads without adding unnecessary weight, contributing to better overall performance and fuel efficiency in vehicles and machinery.

Common Applications

- Automotive components: engine blocks, gears, and shafts

- Aerospace components: structural parts

- Heavy machinery: transmission shafts, gears

2. Excellent Toughness and Impact Resistance

40Mn2 steel is known for its toughness, which is the ability of a material to absorb energy without fracturing. Toughness is a vital property in applications that face high impact forces, such as in the manufacturing of parts for heavy machinery, automotive, and mining equipment.

How Toughness Improves Performance

The toughness of 40Mn2 steel allows it to withstand shock loads, making it a preferred choice for parts exposed to high stress and extreme operating conditions. For example, in automotive engineering, components like crankshafts or axles need to absorb shocks during operation without cracking or breaking. 40Mn2 steel offers durability, ensuring longevity and reliability for these critical parts.

Applications

- Heavy-duty vehicle components: gears, axle shafts

- Mining tools: drill bits, impact-resistant parts

3. Good Wear Resistance

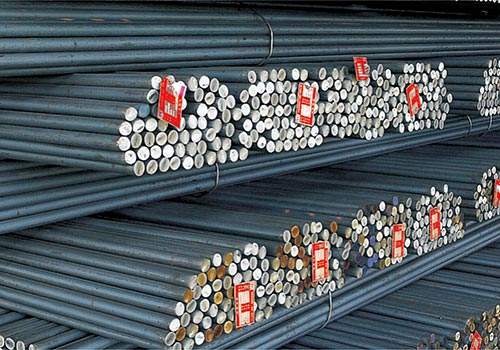

Another important property of 40Mn2 steel is its wear resistance, which allows it to maintain its structural integrity even under abrasive conditions. Parts made from this steel can endure prolonged exposure to friction and wear, making it an excellent choice for industries where machinery is subject to constant movement and abrasion.

The Importance of Wear Resistance

Wear resistance directly contributes to the lifespan of parts, reducing the need for frequent replacements and maintenance. For example, in the automotive industry, brake components, clutch parts, and gears made from 40Mn2 steel can last longer, improving overall performance and reducing downtime.

Key Industries

- Automotive: brake pads, clutch discs

- Mining: wear-resistant drill rods, pumps

- Construction: excavator arms, crane hooks

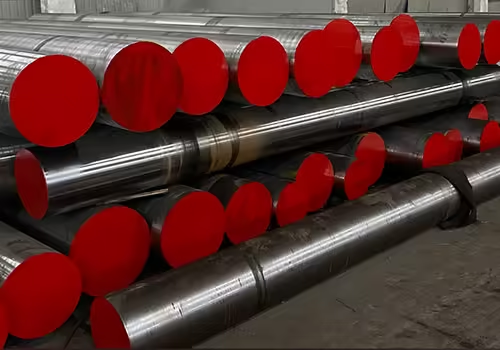

4. Heat Treatment Flexibility

One of the major advantages of 40Mn2 steel is its ability to be heat-treated to adjust its mechanical properties. By using processes like quenching, tempering, and annealing, the hardness, toughness, and strength of 40Mn2 steel can be customized to meet specific application requirements.

Why Heat Treatment is Crucial

Heat treatment processes allow manufacturers to fine-tune the steel’s properties based on the intended use. For example, by increasing the hardness of 40Mn2 steel through heat treatment, it can become more suitable for tools and components that will face high abrasion. Alternatively, tempering the steel can enhance its toughness for use in parts that need to resist impact forces.

Industries Benefiting from Heat Treatment

- Automotive: engine components, camshafts

- Heavy machinery: cutting tools, drill bits

- Tool manufacturing: molds, dies

5. Good Weldability

40Mn2 steel has good weldability, making it easier to join with other materials during the manufacturing process. This property is essential in industries that require complex assemblies or multi-component systems.

Why Weldability Matters

Weldability ensures that components can be fabricated without the risk of cracks or defects in the welded joints. This is especially critical in the production of large structures, machinery, or high-performance components. 40Mn2 steel’s ability to maintain its integrity after welding makes it an attractive material for engineers working on complex designs.

Common Applications

- Heavy equipment: weldments for machinery

- Automotive: vehicle frames, body panels

- Structural steel: bridges, buildings

Table: Comparison of 40Mn2 Steel with Other Steel Grades

| Steel Grade | Tensile Strength (MPa) | Wear Resistance | Toughness | Weldability | Heat Treatment |

|---|---|---|---|---|---|

| 40Mn2 Steel | 600-750 | High | High | Good | Excellent |

| 4140 Steel | 650-850 | Medium | Medium | Good | Excellent |

| 1045 Steel | 570-700 | Medium | Medium | Good | Good |

| 8620 Steel | 600-800 | Medium | High | Good | Excellent |

The table above compares 40Mn2 steel with other popular steel grades. As seen, 40Mn2 steel stands out in terms of wear resistance, toughness, and heat treatment flexibility, making it a superior choice for high-performance applications.

Conclusion

40Mn2 steel offers a unique combination of properties that make it an excellent choice for a wide range of industrial applications. From its impressive strength-to-weight ratio to its excellent wear resistance and toughness, 40Mn2 steel ensures durability and reliability in demanding environments. Whether you are manufacturing automotive parts, heavy machinery components, or industrial tools, 40Mn2 steel is a versatile and cost-effective material that can meet your needs. Understanding its key properties—strength, toughness, wear resistance, heat treatment flexibility, and weldability—will help you make the best material selection for your projects.

FAQ

1. What industries use 40Mn2 steel?

40Mn2 steel is used in industries such as automotive, aerospace, mining, construction, and manufacturing, where high strength, toughness, and wear resistance are required.

2. How does heat treatment affect 40Mn2 steel?

Heat treatment can enhance 40Mn2 steel’s hardness, toughness, and strength. By adjusting the heat treatment process, the steel can be tailored to meet the specific needs of the application.

3. Is 40Mn2 steel suitable for welding?

Yes, 40Mn2 steel has good weldability, making it suitable for applications that require welding of complex components or multi-part assemblies.

4. What is the wear resistance of 40Mn2 steel?

40Mn2 steel has high wear resistance, making it ideal for parts exposed to constant friction and wear, such as gears, brake pads, and drill bits.

5. Can 40Mn2 steel be used in high-temperature environments?

Yes, 40Mn2 steel performs well in high-temperature environments, thanks to its toughness and ability to withstand thermal stress, making it suitable for applications like automotive engines and heavy machinery.