52100 Steel: A Century of Excellent Proof

Table of Contents

Introduction

In the vast realm of metallurgical innovation, certain materials stand out not only for their exceptional properties but also for their enduring legacy. Among these, 52100 steel holds a distinguished position, particularly as a foundational material for bearings. Known as a high-carbon, chromium-containing steel, 52100 steel boasts superior wear resistance and impressive toughness, making it a critical choice for applications demanding high performance and durability. Its applications extend beyond bearings to include gears and cutting tools, a testament to its versatile capabilities.

The history of 52100 steel in industrial applications is remarkably long and robust. It has been utilized in the manufacturing of bearings since at least 1905, establishing a benchmark for reliability and strength that has spanned over a century. This long-standing presence in critical components underscores the steel’s design excellence and its proven ability to withstand the rigors of time and demanding operational environments. This blog post will delve into the intricate details of 52100 steel, exploring its elemental composition, the precise methods required for its heat treatment, and its remarkable suitability for crafting high-performance knives. Through this exploration, we aim to illuminate why 52100 steel continues to be a cornerstone in engineering and manufacturing worldwide.

What is the Composition of 52100 Steel?

The exceptional properties of 52100 steel are intrinsically linked to its carefully balanced elemental composition, which sets it apart from other high-carbon steels. It is essentially a relatively simple steel, yet profoundly effective, primarily composed of approximately 1% carbon and about 1.5% chromium, supplemented by smaller amounts of manganese (Mn) and silicon (Si). Other minor elements, such as phosphorus (P), sulfur (S), nickel (Ni), copper (Cu), and aluminum (Al), are also present, each contributing subtly to the steel’s overall characteristics.

The high carbon content, typically around 1%, is a defining characteristic of 52100 steel, classifying it as a high-carbon steel. This substantial carbon presence is crucial for achieving the remarkable hardness that 52100 steel is known for, enabling it to be hardened to a Rockwell C hardness of 66-68. Carbon is the primary hardening agent, directly influencing the steel’s tensile strength and its ability to maintain a sharp edge, particularly relevant for cutting tools.

The addition of chromium, typically around 1.5%, is another pivotal aspect of 52100 steel’s design. Chromium serves several vital functions. One key purpose is to enhance the steel’s hardenability, which is a measure of how deeply and uniformly the steel can be hardened through heat treatment. Simple carbon steels, like 1095 (which also has nearly 1% carbon but lacks chromium), require extremely fast water quenching to fully harden and form martensite.

In contrast, the chromium in 52100 steel inhibits the formation of pearlite during slower cooling rates, effectively pushing the “nose” of the Time-Temperature Transformation (TTT) curve to longer times. This allows 52100 steel to achieve full hardness with less aggressive quenching methods, such as oil quenching, thereby reducing the risk of deformation and cracking.

Chromium also plays a significant role in improving wear resistance and tensile strength. While it enhances corrosion resistance to a certain extent, it’s important to note that the chromium content in 52100 steel is not high enough to classify it as a stainless steel, meaning it will still be prone to rust without proper maintenance.

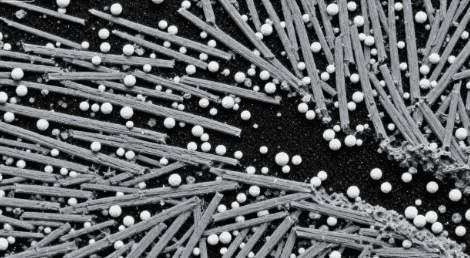

Furthermore, chromium significantly influences the size and distribution of carbides within the steel. Carbides are hard particles that improve wear resistance. The addition of chromium helps to reduce the size of these carbides, leading to better toughness and improved resistance to fracture. 52100 steel is renowned for its very small carbide size and high carbide density, even when compared to other carbon and alloy steels like 1095. This fine carbide structure is achieved during the annealing process, where the steel is slowly cooled from high temperatures, forming spheroidized carbides. Because chromium diffuses slower than carbon and enriches in the cementite within pearlite, it impedes the growth and spheroidization of these carbides, resulting in the desired fine microstructure.

It is worth noting that while 52100 steel contains chromium, it does not have sufficient amounts to form chromium carbides like Cr7C3 or Cr23C6, which are common in higher chromium steels. Instead, some chromium enriches the M3C type carbides, where M can be either iron or chromium, with 52100 cementite typically containing about 9wt% chromium.

The design of 52100 steel has been so effective that it has garnered various other names globally, reflecting its widespread adoption and consistent performance. These include 100Cr6, 1.3505, GCr15, En31, and SUJ2, all referring to essentially the same robust material.

To provide a clearer overview, the typical approximate elemental composition of 52100 steel is presented in the table below, summarizing the key elements and their roles based on available data:

| Element | Approximate Percentage (%) | Role in 52100 Steel |

| Carbon (C) | ~1% | Increases hardness, tensile strength, and edge retention; primary hardening agent. Makes it a high carbon steel. |

| Chromium (Cr) | ~1.5% | Enhances hardenability, wear resistance, tensile strength, and corrosion resistance (though limited for rust prevention). Contributes to carbide formation and refines carbide size. |

| Manganese (Mn) | 0.45-0.5% | Increases hardness and strength. |

| Silicon (Si) | 0.30-0.5% | Improves strength and heat resistance, often used as a deoxidizer. |

| Phosphorus (P) | 0.03% | Improves machinability and hardness, but typically limited as higher amounts can cause brittleness. |

| Sulfur (S) | 0.02% | Improves machinability, but usually kept low as it can reduce toughness and form undesirable inclusions. |

| Nickel (Ni) | 0.30-0.5% | Increases toughness and strength. |

| Copper (Cu) | 0.30-0.5% | Slightly improves corrosion resistance. |

| Aluminum (Al) | 0.05% | Added to refine grain size and improve machinability, often used for deoxidation. |

How to Heat Treat 52100 Steel?

Heat treatment is a crucial process for 52100 steel, allowing its inherent properties to be fully realized, particularly in terms of hardness and strength. While 52100 steel can sometimes be used in its as-rolled state, heat treatment is often necessary to significantly improve its performance for demanding applications. The core of heat treating 52100 steel involves a precise sequence of heating, quenching, and cooling steps.

Steps for Heat Treating 52100 Steel:

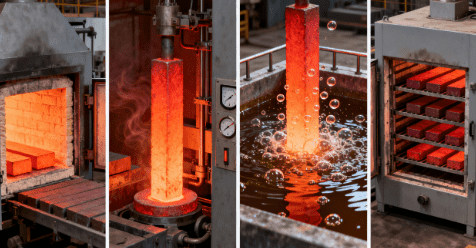

1. Preheating

The process begins by preheating the 52100 steel in a furnace to a temperature between 1,550 and 1,650 degrees Fahrenheit (approximately 843 to 899 degrees Celsius). This initial step ensures a more uniform heating and reduces thermal shock in subsequent stages.

2. Placement

After preheating, the steel should be carefully placed on a heat-treatable surface that ensures uniform heat distribution. This prevents localized overheating or cooling, which could lead to inconsistencies in the final material properties.

3. Austenitization (Heating to Critical Temperature)

The 52100 steel is then heated until it reaches its critical temperature, which is approximately 1,832 degrees Fahrenheit (1,000 degrees Celsius). This stage, known as austenitization, transforms the steel’s microstructure into austenite, a phase capable of dissolving carbon for subsequent hardening. It is crucial that this heating process does not exceed 20 minutes to prevent excessive grain growth or decarburization, which can negatively impact the steel’s properties.

4. Quenching

Immediately after reaching the critical temperature, the 52100 steel must be rapidly cooled, or quenched, in either oil or water. Quenching is the process that “locks in” the hardness by transforming the austenite into martensite, a very hard and brittle microstructure. The choice between oil and water depends on the desired cooling rate; oil quenching generally offers a slower, less aggressive quench compared to water, which can be advantageous for 52100 steel due to its chromium content.

5. Cooling (Annealing/Tempering)

Following the initial quench, the 52100 steel is allowed to cool slowly over several hours. This process, often referred to as annealing or tempering, is performed at a lower temperature than the initial heating and is critical for improving the steel’s toughness and ductility. While quenching makes the steel very hard, it also makes it brittle. Tempering reduces this brittleness, making the steel more resistant to fracture while retaining significant hardness, producing a hardened bearing steel with the necessary characteristics for high-load applications.

Role of Quench Oil

For quenching 52100 steel, specialized quench oils are commonly used. These oils are formulated from a blend of different oils to provide optimal protection during the cooling process. The primary functions of quench oil include preventing oxidation of the metal surface and minimizing the risk of warping and cracking that can occur if the metal cools too rapidly. When using quench oil, it is essential to adhere to the manufacturer’s instructions.

Typically, the oil needs to be preheated to a specific temperature before use, which varies depending on the type of metal being treated. After immersing the metal until it is completely cool, the quench oil can be reused multiple times before it needs to be replaced. Proper storage of quench oil in a cool, dark place is also critical to prolong its lifespan and prevent premature degradation.

Impact of Chromium on Heat Treatment

The presence of chromium in 52100 steel significantly impacts its hardenability compared to simple carbon steels. Chromium increases the hardenability by slowing down the diffusion of atoms, particularly chromium atoms which are larger than carbon. This allows for a less aggressive quench, such as oil, to achieve full hardness, whereas steels like 1095 would require a very fast water quench. This moderate hardenability of 52100 steel is a practical compromise, reducing the risks of deformation and quench cracking that can accompany more severe quenching methods.

During austenitization, the choice of temperature is critical for controlling the amount of carbon dissolved in the austenite and the volume fraction of carbides. For 52100 steel, an austenitizing temperature of approximately 1550°F (843°C) is often recommended, which is higher than that for 1095 steel. This temperature allows for a dissolved carbon content of about 0.63%, which provides maximum hardness without forming undesirable plate martensite, thereby preserving toughness. Lower hardening temperatures can further reduce dissolved carbon, enhancing toughness. The increased carbide content after heat treatment, typically 6-10% volume fraction, also contributes significantly to the wear resistance of 52100 steel.

Compared to air-hardening steels like A2 or D2, 52100 steel, with its lower chromium content, is easier to forge and has a medium-low hardenability that makes it more forgiving to quench. It can also be normalized and annealed through simpler processes, unlike high-hardenability steels that may harden even in air, making annealing difficult without precise temperature control. This combination of properties makes 52100 steel’s heat treatment process a well-balanced compromise for robust and flexible manufacturing.

Is 52100 Steel Good for Knives?

When considering 52100 steel for knife making, the answer is a resounding yes; it can be crafted into excellent and highly versatile knives. Its unique elemental composition and inherent strength make it a prime candidate for blades that can withstand considerable weight and severe impacts. However, like any specialized material, using 52100 steel for knives comes with both significant advantages and specific considerations for maintenance.

Advantages of 52100 Steel for Knives:

Exceptional Hardness and Edge Retention

52100 steel can achieve a Rockwell hardness of between HRC64 and HRC66. This places it among the hardest steels used in knife manufacturing. Such high hardness translates directly into superior edge retention, meaning a 52100 steel blade can hold a sharp edge for extended periods, even under rigorous use. This makes it an ideal choice for hunting knives or other applications where a consistently sharp edge is paramount.

Outstanding Strength and Toughness

Primarily used in mechanical manufacturing for its ability to withstand great weight and intense impact, 52100 steel is exceptionally strong. This strength makes it resistant to breaking or chipping, even during heavy-duty cutting or piercing tasks. The approximately 1% carbon content contributes significantly to this fracture resistance. Tests, including 3-modulus tests (elastic, bulk, and shear moduli) and fracture tests, confirm its ability to endure significant strain and repeated compression while maintaining its strength. Its strength is nearly double that of some other alloys.

Relatively Easy to Sharpen

Despite its impressive hardness, 52100 steel blades are surprisingly easy to sharpen once they eventually begin to lose their edge. Unlike many other hard steels that require specialized equipment or extensive effort, a 52100 steel knife can be sharpened without much difficulty, although it might take a bit longer than softer steels. This is a distinct advantage for users who prefer to maintain their own blades.

Considerations and Maintenance for 52100 Steel Knives:

Workability Challenges

The very strength that makes 52100 steel so desirable for knives also presents a challenge during its processing. It is generally harder to machine and work with compared to other metals commonly used for knife making. Knife makers must account for this increased difficulty in their crafting processes.

Rust and Corrosion Susceptibility

This is the primary drawback of 52100 steel for knife applications. Despite its chromium content, the amount of chromium is insufficient to provide true stainless properties, making 52100 steel susceptible to oxidation, corrosion, and rust. This means that 52100 steel knives require diligent maintenance; they must be cleaned and oiled after each use, especially if exposed to moisture or humid environments. Any liquid left on the blade can quickly lead to rust. For long trips or prolonged exposure to moisture, applying a rust-preventative coating is highly recommended to protect the blade. Without such care, a 52100 steel knife might not be suitable for environments like swamps or extended outdoor excursions.

Machinability in Systems

While it can be easily rolled and cut due to average shear results, its machinability score is around 40% (on a scale of 100%). This means it is mechanically very efficient, but it can wear machine systems faster than some other metals.

In comparison to other popular knife steels like 1095 steel, 52100 steel objectively offers superior durability and better edge retention, making it a preferred choice for many artisans and users seeking high-performance blades. Overall, 52100 steel, while demanding a commitment to maintenance, rewards its users with a knife that offers unparalleled strength, exceptional edge retention, and the ability to withstand the rigors of demanding tasks. Its qualities make it a favorite among knife makers for creating resilient and effective cutting tools.

Conclusion

52100 steel stands as a remarkable testament to enduring metallurgical design, a high-carbon, chromium-containing alloy that has proven its worth across more than a century of industrial application. Its inherent qualities—excellent wear resistance, robust toughness, and the ability to achieve exceptional hardness—have solidified its position as a critical material for bearings, gears, and various cutting tools.

Developed specifically for bearings and in use since at least 1905, the design of 52100 steel has indisputably withstood the test of time, demonstrating its unparalleled reliability and performance under high-stress conditions. The careful balance of its elemental composition, particularly the precise levels of carbon and chromium, endows 52100 steel with its distinctive properties, including enhanced hardenability and refined carbide structures that contribute to its impressive durability and fracture resistance.

The heat treatment process, involving careful preheating, precise austenitization, controlled quenching, and subsequent tempering, is fundamental to unlocking the full potential of 52100 steel, allowing it to reach its characteristic hardness and strength. Furthermore, its adaptability extends beyond traditional industrial uses into specialized applications, such as high-performance knife making. While 52100 steel excels in crafting durable and exceptionally sharp blades, its susceptibility to rust necessitates diligent maintenance, a minor trade-off for its superior cutting performance. In essence, 52100 steel represents a harmonious balance of strength, toughness, and workability, ensuring its continued relevance and esteemed status in the modern engineering landscape.

FAQ

Q1: What is 52100 steel primarily used for?

52100 steel is primarily utilized in applications requiring high wear resistance, toughness, and hardness. It is extensively used for manufacturing bearings, gears, and various cutting tools. Its ability to achieve high hardness through heat treatment makes it ideal for components under high stress and friction.

Q2: Does 52100 steel rust easily?

Yes, 52100 steel is prone to oxidation, corrosion, and rust. Despite containing chromium, the percentage is not high enough to make it stainless steel, meaning it lacks sufficient rust-preventative elements. Therefore, it requires diligent maintenance, such as cleaning and oiling after each use, especially if exposed to moisture or humid environments, to prevent corrosion.

Q3: Is it difficult to sharpen a 52100 steel knife?

Surprisingly, no, it is not difficult to sharpen a 52100 steel knife. Despite its high hardness and excellent edge retention, which often correlates with difficult sharpening in other steels, 52100 steel can be sharpened relatively easily without requiring specialized equipment. It might take slightly longer than softer steels, but it remains manageable for regular maintenance.

Q4: What makes 52100 steel different from simple carbon steels like 1095?

The key difference lies in the addition of chromium in 52100 steel. While both 52100 steel and 1095 steel have a high carbon content (around 1%), the 1.5% chromium in 52100 steel significantly enhances its hardenability, allowing it to achieve full hardness with less aggressive quenching (like oil quenching instead of water quenching) and reducing the risk of cracking. Chromium also refines carbide size and contributes to better toughness and wear resistance, giving 52100 steel a superior balance of properties.