7 Impressive 4140 Steel Uses for Engineers

Table of Contents

Introduction

When discussing versatile alloys, 4140 steel uses stand out prominently in the engineering world. This alloy, known for its superior combination of strength, toughness, and machinability, is widely adopted across many sectors. From automotive to aerospace, understanding the specific 4140 steel uses helps engineers optimize design, enhance durability, and reduce costs. This article delves into seven impressive applications of 4140 steel, highlighting its critical role in modern engineering projects.

Automotive Components: A Key 4140 Steel Use

One of the most significant 4140 steel uses is in the automotive manufacturing sector, where the demand for materials with high strength, toughness, and fatigue resistance is critical. Components such as crankshafts, axles, gears, and connecting rods are routinely manufactured from 4140 steel because these parts experience constant cyclic loads, vibrations, and mechanical stresses during vehicle operation.

The alloy’s high tensile strength allows these components to endure the forces generated by engine combustion and drivetrain torque without deforming or failing prematurely. Additionally, 4140 steel’s fatigue resistance ensures that parts can withstand millions of load cycles without cracks or fractures, which is essential for vehicle safety and longevity.

Heat treatment processes further enhance the properties of 4140 steel, enabling automotive engineers to tailor wear resistance and toughness according to specific applications. For example, carburizing or quenching and tempering can produce parts with a hard surface to resist abrasion while maintaining a ductile core to absorb shocks. This balance helps reduce the risk of catastrophic failure during dynamic loading events like sudden acceleration, braking, or impact, thereby increasing vehicle reliability.

Moreover, 4140 steel offers good machinability, which reduces manufacturing costs and enables precision engineering of complex parts, contributing to improved fuel efficiency and overall vehicle performance. Its relatively good corrosion resistance, when properly treated or coated, extends component service life even in harsh operating environments exposed to moisture, salt, or chemicals.

Aerospace Applications: Vital 4140 Steel Uses for Flight Safety

The aerospace industry demands materials capable of operating reliably under extreme mechanical stresses, temperature fluctuations, and corrosive environments. Within this sector, 4140 steel uses are particularly prevalent in critical components such as landing gear, engine parts, hydraulic systems, and structural supports.

The alloy’s favorable strength-to-weight ratio is one of the key reasons aerospace engineers select 4140 steel. While it is not as lightweight as aluminum or titanium alloys, its excellent mechanical properties allow designers to achieve safety factors and performance benchmarks for components that must endure repeated loading and impact during takeoff, flight, and landing phases.

4140 steel is also valued for its ability to undergo surface hardening treatments like nitriding or induction hardening. These processes create a tough, wear-resistant outer layer that can withstand the intense friction and contact pressures in aerospace mechanisms, while preserving a ductile and shock-absorbing core that prevents brittle failure.

The high-temperature resistance of 4140 steel enables it to function well in engine components exposed to thermal cycles and stress concentrations. This thermal stability helps maintain dimensional integrity and mechanical strength during flight, reducing the risk of deformation or cracking.

In addition, 4140 steel’s versatility and cost-effectiveness make it a reliable choice for both primary and secondary structural parts, enabling aerospace manufacturers to optimize their supply chains without compromising safety or performance.

Oil and Gas Industry Equipment: Essential 4140 Steel Uses in Harsh Conditions

The oil and gas industry operates in some of the most demanding environments on earth, including deep wells where extreme pressures, corrosive fluids, and abrasive materials are common. The importance of selecting materials that can withstand these challenges cannot be overstated, and 4140 steel uses are integral to equipment such as drill collars, tool joints, wellhead components, and downhole tools.

4140 steel’s toughness and fatigue resistance make it well-suited for parts that must endure cyclic loading and bending during drilling operations. Its wear resistance reduces the rate of surface degradation caused by constant contact with rock formations and drilling fluids laden with abrasive particles.

A particularly valuable characteristic of 4140 steel is its resistance to sulfide stress cracking, a form of hydrogen-induced cracking that often affects steel exposed to sour gas (hydrogen sulfide) environments. This resistance extends equipment lifespan and prevents catastrophic failures that could lead to costly downtime or environmental hazards.

Moreover, 4140 steel’s ability to be heat-treated for customized hardness and strength profiles enables manufacturers to produce parts optimized for different operational requirements, balancing toughness with surface durability. The alloy’s machinability further allows for precise fabrication of complex geometries necessary for specialized oilfield tools.

By employing 4140 steel in oil and gas equipment, companies benefit from reduced maintenance frequency, improved operational efficiency, and enhanced safety margins in hazardous working conditions.

Industrial Machinery and Tooling: Robust 4140 Steel Uses

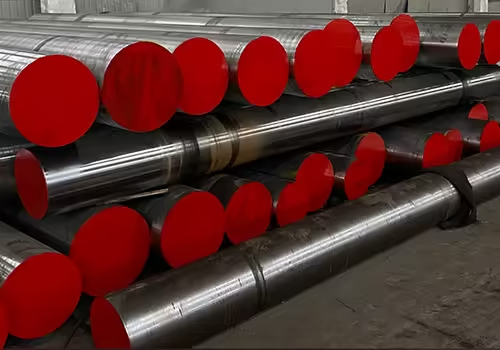

Industrial manufacturing and tooling demand materials that combine strength, precision, and reliability. Among the various 4140 steel uses in this sector are components such as shafts, spindles, dies, molds, and cutting tools.

4140 steel’s excellent machinability allows manufacturers to create parts with complex shapes and tight tolerances, essential for machinery that requires consistent performance and minimal downtime. Once machined, these parts can be heat-treated to achieve high hardness levels on surfaces subjected to wear, while maintaining a resilient core that absorbs shocks and vibrations.

For example, shafts and spindles made from 4140 steel can endure repetitive rotational loads and torsional stresses without permanent deformation. Dies and molds benefit from the alloy’s wear resistance, extending tooling life even when exposed to abrasive materials or cyclic loading.

The dimensional stability of 4140 steel parts is critical in high-precision manufacturing processes where even minor variations can lead to product defects. By minimizing part deformation during service, 4140 steel helps maintain product quality and reduces costly rework.

The overall reliability of machinery components made from 4140 steel supports uninterrupted production lines, enhancing factory productivity and lowering maintenance-related expenses.

Construction and Structural Components: Reliable 4140 Steel Uses

In construction, materials that combine high strength with toughness and durability are essential to ensure safety and longevity of buildings and infrastructure. 4140 steel finds extensive use in structural components such as beams, columns, anchor bolts, and support brackets.

The alloy’s high yield strength enables these components to bear significant loads without permanent deformation, which is vital in resisting forces from wind, earthquakes, or heavy occupancy. Its toughness prevents brittle failure, especially under impact or sudden load changes.

4140 steel’s resistance to fatigue and wear also makes it a practical choice for movable or load-bearing joints and connectors within structures. Engineers can specify this alloy for reinforcement elements where enhanced strength and reliability contribute to overall building integrity.

Furthermore, 4140 steel’s capacity for heat treatment means structural parts can be optimized for specific performance requirements, balancing strength with ductility. This flexibility helps in designing structures that meet stringent building codes and safety standards.

The use of 4140 steel in construction projects contributes to longer service life and reduced maintenance costs, supporting sustainable infrastructure development.

Agricultural Machinery Parts: Durable 4140 Steel Uses

Agriculture machinery often operates in rough terrain and under heavy load conditions, demanding materials that can tolerate abrasion, impact, and cyclic stresses. 4140 steel uses in agricultural equipment include components like tractor axles, plowshares, cultivator tines, and harvester parts.

The alloy’s excellent wear resistance reduces the degradation rate of tools constantly interacting with soil, rocks, and plant debris. This leads to fewer part replacements and lower overall maintenance expenditures.

Additionally, 4140 steel’s toughness allows agricultural components to absorb shocks from uneven ground and heavy workloads without cracking or breaking. This durability is essential for machinery that must perform reliably during extended farming seasons.

The machinability of 4140 steel also enables the production of complex parts that improve the efficiency and versatility of agricultural implements, such as adjustable cultivators or specialized plows.

By leveraging 4140 steel in agricultural machinery, manufacturers provide farmers with equipment that maximizes uptime and productivity, supporting better crop yields and operational cost savings.

Mining Equipment: Heavy-Duty 4140 Steel Uses

Mining environments subject equipment to abrasive wear, impact loads, and exposure to harsh chemicals, making durability a primary concern. 4140 steel uses in mining include drilling bits, conveyor components, crusher parts, and load-bearing structures.

The alloy’s hardness allows mining parts to resist surface wear caused by constant contact with rocks and minerals, extending operational life and reducing replacement frequency. Its impact resistance minimizes damage from heavy loads and shock events common in mining processes.

Furthermore, 4140 steel maintains its mechanical properties under fluctuating temperatures and corrosive environments, essential for equipment operating both underground and on the surface.

Using 4140 steel in mining machinery supports uninterrupted operations and lowers the total cost of ownership, as downtime for repairs or replacements can be highly costly in mining projects.

Cost Savings Breakdown from 4140 Steel Uses

| Application Sector | Key Benefit | Financial Impact |

|---|---|---|

| Automotive Components | Durability and fatigue resistance | Reduces maintenance and failure costs |

| Aerospace Applications | Strength-to-weight ratio | Enhances safety, reduces material waste |

| Oil and Gas Equipment | Corrosion and wear resistance | Extends service life, lowers downtime |

| Industrial Machinery | Machinability and strength | Improves precision, reduces rework |

| Construction Components | High yield strength | Increases structural lifespan |

| Agricultural Machinery | Wear resistance | Cuts repair costs and operational delays |

| Mining Equipment | Impact and abrasion resistance | Decreases replacement frequency |

Conclusion

Understanding the diverse 4140 steel uses is essential for engineers aiming to optimize material performance and cost-efficiency. Its adaptability across various industries, from automotive to mining, underscores its value as a reliable, durable, and cost-effective alloy. Selecting 4140 steel can lead to improved product longevity, reduced maintenance, and enhanced operational efficiency.

FAQ

What makes 4140 steel suitable for high-stress applications?

Its high tensile and yield strength, along with excellent toughness, allow it to withstand significant stress without deformation.

Can 4140 steel be heat-treated?

Yes, 4140 steel responds well to heat treatment processes like quenching and tempering, enhancing its mechanical properties.

Is 4140 steel corrosion-resistant?

While it has some resistance due to its chromium content, it is not as corrosion-resistant as stainless steel and may require protective coatings in corrosive environments.

How does 4140 steel compare to other alloy steels?

4140 steel offers a balanced combination of strength, toughness, and machinability, making it versatile compared to other alloy steels that may excel in specific properties.

What are common forms in which 4140 steel is available?

4140 steel is available in various forms, including bars, plates, sheets, and tubes, catering to different manufacturing needs.