4 Essential Insights Into 4140 Steel Properties

Table of Contents

Introduction

4140 steel is a versatile alloy widely recognized for its mechanical strength, toughness, and resistance to wear. It belongs to the family of low-alloy steels and is commonly used in a variety of industrial applications, ranging from automotive components to construction equipment. Understanding 4140 steel properties is crucial for engineers, fabricators, and designers looking to optimize material performance in demanding environments.

This blog explores four essential insights into 4140 steel properties, helping readers gain a comprehensive understanding of this valuable material. We will delve into its chemical composition, mechanical traits, thermal treatment responses, and common uses, supported by a detailed comparison table. Whether you’re selecting a material for a high-stress application or learning about metal fabrication, knowing the key aspects of 4140 steel properties will empower you to make informed decisions.

Chemical Composition and Microstructure of 4140 Steel Properties

One of the primary attributes that define 4140 steel properties is its chemical makeup. This steel is composed mainly of chromium, molybdenum, and manganese, elements that contribute to its hardness and strength. The balanced combination of alloying elements ensures that the steel can be heat treated for enhanced performance without sacrificing ductility.

The typical chemical composition of 4140 steel includes:

- Carbon: 0.38% – 0.43%

- Chromium: 0.80% – 1.10%

- Manganese: 0.75% – 1.00%

- Molybdenum: 0.15% – 0.25%

- Silicon: 0.15% – 0.35%

This composition results in a microstructure that provides excellent toughness and wear resistance, essential characteristics of 4140 steel properties. When normalized or quenched and tempered, the steel forms a uniform structure that can endure mechanical stress in heavy-duty applications.

Mechanical and Physical Traits of 4140 Steel Properties

4140 steel properties include a combination of mechanical strength and toughness, making it a preferred material in high-stress environments. It offers excellent tensile strength, fatigue resistance, and impact toughness, all of which are enhanced by heat treatment processes.

Here is a detailed table outlining the typical mechanical and physical properties of 4140 steel:

| Property | Value (Typical) | Description |

|---|---|---|

| Density | 7.85 g/cm³ | Average density for low-alloy steel |

| Tensile Strength | 655 MPa – 1080 MPa | Increases with heat treatment |

| Yield Strength | 415 MPa – 930 MPa | Depends on tempering process |

| Elongation at Break (%) | 20% – 25% | Indicates good ductility |

| Hardness (Brinell) | 197 – 300 HB | Varies by tempering and quenching |

| Modulus of Elasticity | 205 GPa | Standard for steel |

These properties enable 4140 steel to perform in high-load scenarios such as automotive drive shafts, crankshafts, and heavy machinery parts. Its fatigue resistance ensures longevity in dynamic loading conditions, while its ductility supports forming and machining operations.

Thermal Treatment and Its Effects on 4140 Steel Properties

One of the most valuable aspects of 4140 steel properties is the material’s responsiveness to heat treatment. Through various processes such as annealing, normalizing, quenching, and tempering, the mechanical characteristics of the steel can be significantly altered to meet specific application needs.

- Annealing softens the steel, improving machinability and refining grain structure.

- Normalizing results in a uniform grain size, enhancing toughness and structural stability.

- Quenching and tempering dramatically increase strength and hardness, crucial for components subjected to high stress.

These processes make 4140 steel suitable for applications requiring precise control over hardness and strength. For example, parts exposed to cyclical stress benefit from quenched and tempered steel due to its improved fatigue strength and surface durability. The thermal treatment process is essential in tailoring 4140 steel properties to specific operational demands, thereby expanding its usefulness across multiple industries.

Industrial Applications Leveraging 4140 Steel Properties

Thanks to its balanced mechanical and chemical characteristics, 4140 steel finds application in numerous industries. Its unique combination of toughness, wear resistance, and heat treatment versatility allows it to replace more expensive materials without compromising performance.

Common industrial uses include:

- Automotive: crankshafts, gear shafts, and axles

- Oil and gas: drill collars, tool joints, and structural components

- Construction: high-strength fasteners and heavy equipment parts

- Tooling: dies, molds, and cutting tools

- Aerospace: landing gear components and other structural elements

Each of these applications leverages 4140 steel properties for enhanced durability, cost efficiency, and mechanical performance. In highly regulated sectors such as aerospace and oil and gas, the predictability and reliability of 4140 steel make it a preferred material.

Conclusion

A thorough understanding of 4140 steel properties allows designers and engineers to exploit its full potential in high-demand applications. From its robust chemical makeup to its outstanding mechanical strength and adaptability to heat treatment, 4140 steel delivers a combination of benefits that few other materials can match.

By mastering how these properties interact and can be modified through processing, professionals can make better material choices for critical applications. Whether you are manufacturing industrial machinery or specifying materials for structural components, the dependable nature of 4140 steel ensures optimal performance, safety, and longevity.

FAQ

What makes 4140 steel different from other alloy steels?

4140 steel properties include a balanced mix of chromium and molybdenum, which provide superior toughness and wear resistance compared to many other low-alloy steels.

Can 4140 steel be welded easily?

While weldable, 4140 steel requires preheating and post-weld heat treatment to prevent cracking and maintain mechanical integrity.

Is 4140 steel corrosion resistant?

4140 steel is not inherently corrosion-resistant and should be coated or plated if used in corrosive environments.

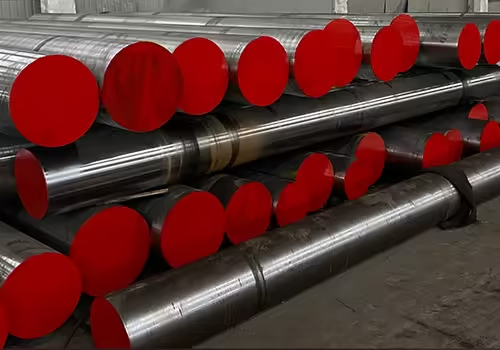

How is 4140 steel commonly supplied?

4140 steel is typically available in rounds, bars, and plates, both in annealed and heat-treated conditions.

What industries use 4140 steel the most?

Major users include automotive, oil and gas, construction, aerospace, and tooling industries, thanks to the versatility of 4140 steel properties.