3 Powerful Tips for Low Carbon Steel Buyers

Table of Contents

Introduction

Low carbon steel has earned a reputation as one of the most versatile and economical materials used in a broad range of industries. Known for its relatively low percentage of carbon—typically below 0.3%—this type of steel is prized for its ductility, malleability, and ease of fabrication. From construction and automotive applications to pipelines, fencing, and machinery parts, low carbon steel has become a staple material for engineers, contractors, and manufacturers alike.

Despite its widespread usage, many buyers—especially those new to industrial procurement—struggle to make well-informed purchasing decisions. Whether it’s due to lack of experience, confusing specifications, or market inconsistency, sourcing low carbon steel effectively is often more complex than it seems.

This comprehensive guide explores three powerful tips that every buyer should know before placing an order. Along the way, we will examine how to assess quality, select the right supplier, understand certifications, and avoid common pitfalls. A detailed comparison table is also provided to help differentiate between common types of low carbon steel.

Understanding the Basics: What Is Low Carbon Steel?

Before diving into expert tips, it’s crucial to have a clear understanding of what low carbon steel really is and why it is so widely used.

Low carbon steel, also known as mild steel, typically contains 0.05% to 0.25% carbon. The low carbon content makes it softer, more workable, and less brittle compared to medium or high carbon steels. However, this softness also means that it’s not as strong or wear-resistant, making it less suitable for heavy-load applications without additional treatment.

Key Properties of Low Carbon Steel:

- High ductility and formability

- Easy to weld and machine

- Cost-effective

- Suitable for galvanizing and coating

- Lower tensile strength compared to alloy steels

Common forms of low carbon steel include sheets, bars, pipes, and structural components. Understanding the application and environment in which the steel will be used is essential when selecting the proper grade or format.

Tip 1: Verify the Chemical and Mechanical Properties Before Buying

When sourcing low carbon steel, one of the most common mistakes buyers make is assuming all grades are the same. This misunderstanding can lead to unexpected performance issues, failed inspections, or costly rework. The first powerful tip for low carbon steel buyers is to always verify the material’s chemical composition and mechanical characteristics.

Key Metrics to Check:

- Carbon Content: Typically < 0.25%

- Yield Strength: Varies by grade, generally low

- Tensile Strength: Between 270–410 MPa

- Elongation: Often high due to ductility

- Hardness: Relatively low on the Brinell scale

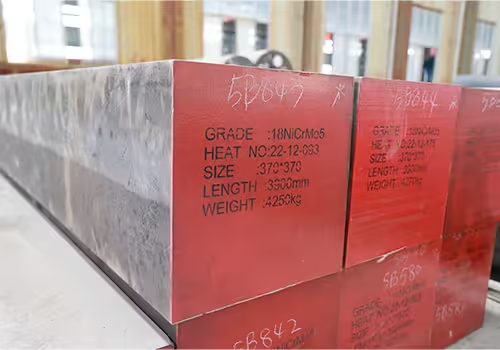

Material Test Certificates (MTCs) should be requested for every batch of steel you purchase. These documents confirm that the supplied material meets the required standards and specifications.

Recommended Actions:

- Ask for third-party certification from reputable testing labs

- Compare the values with ASTM, DIN, or JIS standards

- Request a physical sample for independent verification if the quantity is large

Buying low carbon steel without confirming its properties is like buying a car without checking the engine—risky and potentially costly.

Tip 2: Choose the Right Supplier Based on Reliability and Transparency

Selecting the right supplier is often more important than the product itself. Not all low carbon steel vendors are created equal, and choosing one based purely on price can be a mistake. The second powerful tip for low carbon steel buyers is to focus on supplier transparency, quality control, and track record.

How to Evaluate a Supplier:

- Years in Business: Experienced suppliers tend to offer more consistent quality

- Certifications: Look for ISO 9001 or other international quality standards

- Client Testimonials: Real-world feedback is more telling than product brochures

- Logistics Capability: Ensure the supplier can handle customs, shipping, and tracking efficiently

- Product Range: A wide selection may indicate better access to mills and stock

Here is a comparison table to help you assess supplier qualifications more effectively:

| Evaluation Criteria | High-Reliability Supplier | Medium-Reliability Supplier | Low-Reliability Supplier |

|---|---|---|---|

| Years in Operation | 10+ years | 3–9 years | < 3 years |

| Certifications Provided | ISO, ASTM, EN | Limited local certifications | None or unverifiable |

| Response Time | < 12 hours | 12–48 hours | Slow or inconsistent |

| Quality Documentation | Full MTCs, test reports, RoHS | Partial documents | No documentation |

| Shipping Transparency | Real-time tracking available | Limited updates | No tracking or frequent delays |

A reliable supplier not only provides good products but also supports your workflow by reducing delays, minimizing risks, and ensuring compliance with project standards.

Tip 3: Understand Applications and Match the Right Grade

Low carbon steel comes in a variety of grades and finishes, and the third powerful tip is to match the material to your specific application needs. This includes considering the environmental conditions, load requirements, and fabrication processes involved.

Common Applications of Low Carbon Steel:

- Construction: Beams, rebar, and roofing panels

- Automotive: Body panels, chassis parts, fuel tanks

- Pipelines: Water, gas, and oil lines

- Agricultural Equipment: Fencing, frames, tools

- Furniture and Appliances: Sheet metal enclosures and mounts

Each application may demand a slightly different grade of low carbon steel. For example, deep-drawing applications may require a grade with superior elongation, while outdoor use might demand galvanized low carbon steel to prevent corrosion.

How to Choose the Right Grade:

- Consult with your design or engineering team

- Reference international standards like ASTM A36, A283, or EN 10025

- Consider post-processing needs such as coating, welding, or bending

A mismatch in grade and application can lead to product failure, regulatory non-compliance, or increased operational costs.

Additional Considerations When Buying Low Carbon Steel

Beyond the three core tips discussed earlier, successful procurement of low carbon steel also depends on how well you address additional, often overlooked factors. These considerations can significantly affect the material’s performance, cost-effectiveness, and overall project efficiency. Understanding these elements will help you make informed choices that go beyond just specifications and supplier evaluations.

Consider Surface Treatments:

Low carbon steel, while easy to work with, is also more prone to rust and corrosion compared to stainless or alloyed steels. This is why surface treatments play a crucial role, especially in environments with high humidity, salt exposure, or industrial pollutants.

Among the most common surface treatments:

- Galvanization: A zinc coating that protects steel from oxidation. It’s widely used in outdoor structures, utility poles, fencing, and roofing. Galvanized low carbon steel offers excellent corrosion resistance without compromising weldability.

- Painting: Provides both corrosion protection and visual appeal. Often used in architectural applications where aesthetics are a consideration.

- Powder Coating: A dry finishing process that adds a durable and decorative layer. It’s ideal for products subject to mechanical wear or color coding.

When evaluating low carbon steel options, always inquire about pre-treated materials or the feasibility of applying surface treatments after fabrication. This can reduce future maintenance costs and extend the material’s service life.

Analyze Cost vs. Performance:

One of the most attractive qualities of low carbon steel is its affordability. However, the lowest upfront cost doesn’t always equal the best value. In many cases, slightly more expensive grades or steel with better surface finishes may lead to lower lifecycle costs.

For example:

- A basic untreated sheet might save money today but could corrode within months in a coastal climate, requiring premature replacement.

- A galvanized or coated version might cost more initially but could last 3–5 times longer with minimal maintenance.

It’s essential to perform a Total Cost of Ownership (TCO) analysis when selecting materials. Include not just purchase price, but also shipping, storage, installation, finishing, and projected lifespan. This holistic view helps avoid false economies and ensures more sustainable material choices.

Evaluate Global vs. Local Suppliers:

Choosing between domestic and international suppliers is another key decision point. Each option offers distinct advantages and potential drawbacks.

Local Suppliers:

- Pros: Faster lead times, easier communication, site visits, simplified logistics, and usually quicker dispute resolution.

- Cons: Limited selection or higher pricing due to smaller scale or regional demand.

International Suppliers:

- Pros: Competitive pricing, larger variety of low carbon steel grades and formats, access to major steel-producing regions.

- Cons: Longer shipping times, language barriers, customs complications, and higher minimum order quantities (MOQs).

To make the right choice:

- Evaluate the urgency of your project timeline.

- Consider the size and frequency of your orders.

- Research the trade reputation and quality standards compliance of overseas vendors.

- Account for potential tariffs or import taxes that may affect landed cost.

In many cases, a hybrid sourcing strategy—where base stock is sourced internationally while urgent or customized needs are fulfilled locally—can provide the best of both worlds.

Don’t Forget Environmental and Compliance Requirements

As sustainability becomes a growing concern across industries, it’s important to ensure that your low carbon steel procurement aligns with environmental regulations and corporate responsibility goals.

- Check if the steel is produced from recycled materials.

- Verify if the supplier complies with RoHS, REACH, or ISO 14001 environmental management standards.

- Ask about carbon footprint disclosures, especially if your company must report Scope 3 emissions in its supply chain.

Adhering to these standards not only reduces environmental impact but can also position your brand as a responsible and future-ready organization.

Conclusion

Buying low carbon steel is not just about finding the lowest price. It requires a thoughtful evaluation of specifications, supplier credentials, and application requirements. By following the three powerful tips outlined in this guide—verifying material properties, selecting transparent suppliers, and aligning the steel grade with your application—you can make smarter, more informed purchasing decisions.

Doing so not only reduces the risk of failure or rework but also ensures that your projects are completed on time, on budget, and in full compliance with engineering standards. With low carbon steel being such a widely used material across industries, taking the time to source it properly is an investment in long-term success.

FAQ

What is the typical carbon content in low carbon steel?

Low carbon steel generally contains less than 0.25% carbon. This low percentage makes it easier to machine and form, which is why it’s also referred to as mild steel.

How do I ensure the steel I buy is truly low carbon?

Ask your supplier for a Material Test Certificate (MTC) that lists the chemical composition. You can also send a sample for independent third-party testing if necessary.

Is low carbon steel suitable for welding?

Yes, its low carbon content makes it highly weldable. However, always ensure that the welding process is appropriate for the specific grade and thickness.

What’s the difference between low and high carbon steel?

High carbon steel has greater hardness and strength but is more brittle and harder to work with. Low carbon steel is softer, more ductile, and easier to weld or machine.

Can low carbon steel be used outdoors?

It can be used outdoors if properly coated or galvanized. Without protective treatment, it is prone to corrosion when exposed to moisture and oxygen.

Should I choose hot-rolled or cold-rolled low carbon steel?

Hot-rolled steel is better for structural uses where precision isn’t critical. Cold-rolled steel is smoother and better for precision parts or visual applications.

What are common international standards for low carbon steel?

Standards include ASTM A36 (USA), EN 10025 (Europe), and JIS G3101 (Japan), among others. These help define the mechanical properties and chemical composition.