How 4140 Heat Treating Enhances Steel Durability

Introduction

Steel is one of the most commonly used materials in various industries, from construction to automotive and aerospace. However, not all steels are created equal. The properties of steel can be significantly altered by applying different heat treatment processes. One such steel, 4140, is known for its strength, toughness, and versatility, particularly after undergoing heat treatment. The 4140 heat treat process enhances the durability of this alloy, making it suitable for high-stress applications. In this blog, we’ll explore how the 4140 heat treat process works, the benefits it provides, and how it can be optimized for specific applications.

What is 4140 Steel?

Key Properties of 4140 Steel

4140 is a low-alloy steel that contains chromium, molybdenum, and manganese. These elements give 4140 its high tensile strength, hardenability, and resistance to wear and corrosion. It is often used in industries that require high-strength materials, such as automotive, oil and gas, and heavy machinery manufacturing.

Some of the key properties of 4140 steel include:

- Tensile strength: 4140 steel has excellent tensile strength, which allows it to withstand high levels of stress without breaking or deforming.

- Hardenability: Due to its alloying elements, 4140 can be easily hardened through heat treatment, improving its strength and wear resistance.

- Toughness: The steel maintains good toughness, allowing it to absorb energy and resist fractures even in demanding applications.

- Corrosion resistance: While not as corrosion-resistant as stainless steel, 4140 does offer moderate protection against rust and environmental wear.

The 4140 Heat Treat Process

Overview of Heat Treatment

Heat treatment involves heating and cooling a material in a controlled manner to alter its physical and mechanical properties. The goal is to increase hardness, toughness, and strength. The 4140 heat treat process typically includes several steps, including quenching, tempering, and annealing.

Quenching 4140 Steel

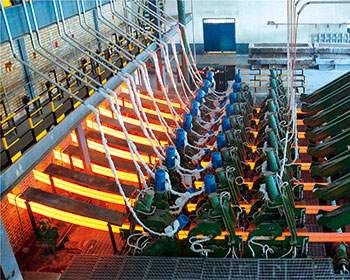

Quenching is the process of rapidly cooling the steel after it has been heated to its austenitizing temperature (around 850-900°C for 4140 steel). This rapid cooling usually involves immersion in oil or water. Quenching increases the hardness of 4140 steel by transforming its microstructure into martensite, a hard and brittle phase.

Tempering 4140 Steel

After quenching, 4140 steel is typically tempered. Tempering involves reheating the steel to a lower temperature (typically between 150-650°C) and then allowing it to cool slowly. This process reduces the brittleness of the material, improves toughness, and retains much of the hardness gained during quenching.

Normalizing 4140 Steel

Normalizing is another heat treatment process used for 4140 steel. It involves heating the steel to a high temperature and then air cooling it. This step refines the grain structure, leading to more uniform mechanical properties. Normalized 4140 steel is often used when a balance between strength and ductility is required.

How 4140 Heat Treat Enhances Durability

Increased Strength and Hardness

One of the primary goals of heat treating 4140 steel is to increase its strength and hardness. Quenching and tempering help to achieve this by modifying the steel’s microstructure. Martensitic transformation during quenching significantly increases hardness, making the steel more resistant to wear and deformation.

Improved Toughness

Toughness is the ability of a material to absorb energy and resist fractures. The tempering process following quenching ensures that 4140 steel retains its toughness, even after becoming harder. By carefully controlling the tempering temperature, you can optimize the steel’s toughness while maintaining adequate hardness.

Enhanced Wear Resistance

For applications where the material is subject to friction and wear, the 4140 heat treat process improves wear resistance. The increased hardness gained from quenching makes the steel more resistant to abrasion, while the tempering process ensures it does not become too brittle and prone to cracking.

Resistance to Fatigue

Fatigue failure occurs when a material undergoes repeated cycles of stress, eventually causing cracks to form. The combination of strength and toughness imparted by the 4140 heat treat process helps the material resist fatigue failure, making it suitable for components like gears, shafts, and other parts exposed to cyclical loads.

Table: Key Mechanical Properties of 4140 Steel Before and After Heat Treatment

| Property | As-Received 4140 Steel | Heat-Treated 4140 Steel |

|---|---|---|

| Tensile Strength (MPa) | 655 | 950-1000 |

| Hardness (HB) | 197-241 | 285-340 |

| Toughness | Moderate | High |

| Wear Resistance | Moderate | High |

| Ductility | High | Moderate |

| Fatigue Resistance | Moderate | High |

This table highlights the significant improvements in mechanical properties that 4140 steel undergoes after heat treatment. The steel becomes stronger, harder, and more resistant to wear and fatigue, making it ideal for demanding applications.

Applications of Heat-Treated 4140 Steel

Automotive Components

4140 heat-treated steel is commonly used in automotive components such as crankshafts, gears, and axles. These parts are subject to high levels of stress and require a material that can withstand fatigue, wear, and impact without failing.

Oil and Gas Industry

In the oil and gas industry, heat-treated 4140 steel is used for drill collars, tool joints, and other components that operate in harsh environments. The steel’s toughness and wear resistance ensure long-term durability in these demanding applications.

Heavy Machinery

Heavy machinery often relies on heat-treated 4140 steel for parts such as gears, shafts, and fasteners. The strength and durability provided by the heat treatment process make the steel capable of handling high loads and repeated use.

Construction Equipment

Construction equipment such as excavator pins and bushings benefit from the increased wear resistance and toughness of heat-treated 4140 steel. These parts are subject to continuous friction and impact, making durability a key factor in material selection.

Conclusion

The 4140 heat treat process plays a crucial role in enhancing the durability of this versatile steel. By undergoing quenching, tempering, and sometimes normalizing, 4140 steel can be optimized for a wide range of applications where strength, toughness, and wear resistance are essential. Whether you are working in the automotive, oil and gas, or heavy machinery industry, understanding how 4140 heat treating enhances steel durability can help you select the right material for your project.

FAQ

What is the purpose of quenching in the 4140 heat treat process?

Quenching is used to rapidly cool the steel after it has been heated, transforming its microstructure to increase hardness and strength. It is a critical step in enhancing the durability of 4140 steel.

How does tempering affect the properties of 4140 steel?

Tempering reduces the brittleness of quenched 4140 steel while maintaining much of its hardness. It improves the steel’s toughness, making it more resistant to fractures and wear.

Can 4140 steel be normalized instead of quenched and tempered?

Yes, normalizing is another heat treatment option for 4140 steel. It improves toughness and ductility but does not provide as much hardness as quenching and tempering.

What is the ideal temperature for tempering 4140 steel?

The ideal tempering temperature for 4140 steel depends on the desired balance of hardness and toughness. Tempering between 150-650°C can be used to adjust the material’s properties for different applications.

How does 4140 heat-treated steel compare to non-heat-treated steel?

Heat-treated 4140 steel is significantly stronger, harder, and more wear-resistant than its non-heat-treated counterpart. It also has better fatigue resistance, making it suitable for high-stress applications.

What industries commonly use 4140 heat-treated steel?

Industries such as automotive, oil and gas, heavy machinery, and construction commonly use heat-treated 4140 steel for components that require high strength and durability.

How can I determine the right heat treatment process for my project?

The right heat treatment process depends on your specific application requirements, such as desired hardness, toughness, and wear resistance. Consulting with a metallurgist or heat-treating expert can help you select the best process for your project.

Is 4140 steel corrosion-resistant after heat treatment?

While 4140 steel offers moderate corrosion resistance due to its alloying elements, it is not as corrosion-resistant as stainless steel. For environments with high corrosion risks, additional coatings or treatments may be necessary.

Can 4140 heat-treated steel be welded?

Yes, 4140 steel can be welded, but it requires preheating and post-weld heat treatment to prevent cracking and ensure the steel retains its mechanical properties.

How does heat treatment affect the machinability of 4140 steel?

Heat treatment increases the hardness of 4140 steel, which can make it more challenging to machine. However, using carbide cutting tools and adjusting machining parameters can help maintain precision.