Rods of Steel vs. Fiberglass: Which Performs Better?

Table of Contents

Introduction

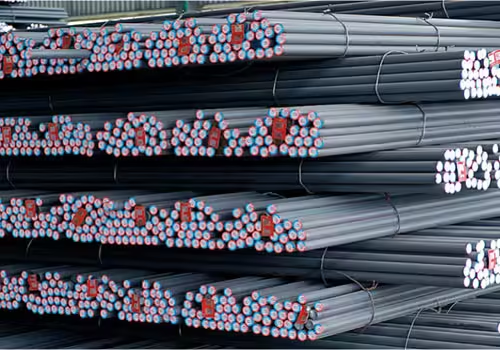

When it comes to choosing between rods of steel and fiberglass for industrial applications, the debate often centers on strength, durability, and cost-effectiveness. While fiberglass has gained popularity in certain sectors due to its lightweight properties, rods of steel remain the superior choice for high-performance applications. This article explores the key differences between these materials, highlighting why steel rods outperform fiberglass in most scenarios.

Why Rods of Steel Are the Superior Choice

1. Unmatched Strength and Durability

Rods of steel are renowned for their exceptional tensile strength and resistance to deformation. Unlike fiberglass, which can weaken under prolonged stress, steel maintains its structural integrity even under extreme conditions. This makes rods of steel ideal for construction, automotive, and heavy machinery applications where reliability is critical.

2. Higher Load-Bearing Capacity

Steel rods can support significantly heavier loads compared to fiberglass. Their high yield strength ensures they do not bend or break under pressure, making them indispensable in infrastructure projects like bridges, high-rise buildings, and industrial equipment.

3. Superior Heat and Fire Resistance

Fiberglass may degrade or melt at high temperatures, whereas rods of steel retain their strength even in extreme heat. This property is crucial in industries such as petrochemicals, power plants, and automotive manufacturing, where materials must withstand high thermal stress.

4. Longer Lifespan and Lower Maintenance Costs

Steel rods are highly resistant to wear and tear, reducing the need for frequent replacements. Fiberglass, on the other hand, may require more maintenance due to its susceptibility to cracking and UV degradation. Over time, rods of steel prove to be more cost-effective.

5. Better Environmental Adaptability

Steel performs well in diverse climates, from freezing temperatures to scorching heat. Fiberglass can become brittle in cold weather and may expand or warp under temperature fluctuations, making steel the more reliable option for outdoor and industrial use.

Comparison Table: Steel Rods vs. Fiberglass

| Property | Rods of Steel | Fiberglass |

|---|---|---|

| Tensile Strength | Very High | Moderate |

| Load-Bearing Capacity | Excellent | Limited |

| Heat Resistance | High | Low to Medium |

| Durability | Long-lasting | Prone to wear |

| Maintenance Requirements | Low | Moderate |

| Cost-Effectiveness | High | Variable |

Common Applications of Rods of Steel

1. Construction and Infrastructure

Rods of steel are widely used in reinforced concrete structures, bridges, and skyscrapers due to their unmatched strength and stability.

2. Automotive and Heavy Machinery

Steel rods are essential in manufacturing engine components, chassis, and transmission systems, where high strength and fatigue resistance are required.

3. Marine and Offshore Engineering

Their corrosion-resistant variants make steel rods perfect for shipbuilding, oil rigs, and underwater structures.

4. Energy and Power Generation

From wind turbines to nuclear plants, steel rods provide the structural support needed for large-scale energy projects.

Conclusion

While fiberglass has its niche applications, rods of steel outperform it in nearly every critical aspect—strength, durability, heat resistance, and cost-efficiency. For industries that demand reliability and long-term performance, steel remains the undisputed champion.

FAQ

Are rods of steel more expensive than fiberglass?

While steel may have a higher initial cost, its longevity and lower maintenance needs make it more economical in the long run.

Can fiberglass replace steel in construction?

In some lightweight applications, yes. However, for load-bearing structures, rods of steel remain irreplaceable.

How does steel perform in corrosive environments?

With proper coatings and alloys, steel rods can resist corrosion effectively, making them suitable for marine and industrial use.

Is steel recyclable?

Yes, steel is 100% recyclable, making it an environmentally sustainable choice.

About Henan Jiyuan Iron & Steel (Group) Co., Ltd.

Founded in 1958, Henan Jiyuan Iron & Steel (Group) Co., Ltd. is a leading steel manufacturer in China, recognized among the Top 500 Chinese Enterprises and Top 100 Global Iron and Steel Enterprises. With advanced technology and a strong R&D base, we specialize in producing high-quality rods of steel for automotive, construction, and industrial applications.

Our products are exported worldwide, meeting stringent international standards, including ISO9001, IATF16949, and China Classification Society certifications. Whether you need standard steel rods or customized solutions, Jiyuan Steel delivers excellence.

Why Choose Jiyuan Steel?

✔ High-performance steel products

✔ Customized steel solutions

✔ Rigorous quality control

✔ Global industry recognition

Contact us today to discuss your steel requirements and discover why leading industries trust Jiyuan Steel for superior performance and reliability.