8 Powerful Applications of 42crmo4 Material Properties

Table of Contents

Introduction

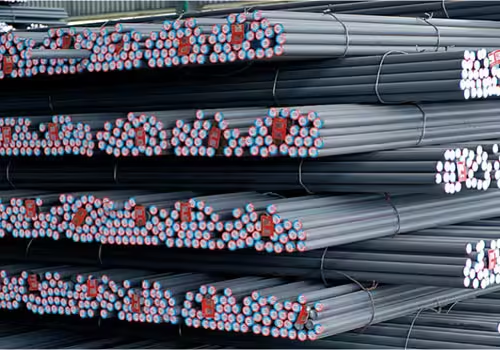

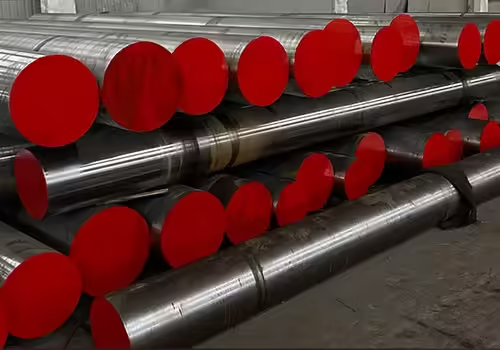

When engineers seek high-performance materials that offer superior mechanical strength, durability, and resistance under challenging conditions, 42crmo4 material properties quickly come to mind. This alloy steel is renowned for its excellent tensile strength, toughness, wear resistance, and ability to withstand high levels of stress, making it an indispensable material across various industries. Whether used in automotive manufacturing, aerospace engineering, or heavy-duty machinery, 42crmo4 material properties provide a balanced composition that ensures both longevity and reliability in even the most demanding applications.

In this blog, we will explore the top eight applications of 42crmo4 material properties, explaining why this steel grade continues to be a key material choice in modern engineering.

Automotive Industry: Reliable Performance in High-Stress Components

42crmo4 material properties make it an essential component in the automotive industry, where strength, fatigue resistance, and long-term performance are critical. Automotive components such as crankshafts, axles, gears, and suspension parts are often fabricated using 42crmo4 due to its exceptional ability to handle high mechanical stress and pressure.

Why Automotive Manufacturers Choose 42crmo4 Material Properties

- High tensile strength: The robust tensile strength of 42crmo4 prevents the deformation of parts under extreme loads.

- Fatigue resistance: Automotive parts made from 42crmo4 can endure high-stress cycles without failure, ensuring extended operational life.

- Wear resistance: The alloy’s inherent wear resistance significantly reduces maintenance costs.

Aerospace Components: Strength Under Extreme Conditions

Aerospace engineering requires materials that can withstand extreme conditions such as high altitudes, temperature fluctuations, and immense mechanical loads. 42crmo4 material properties are ideal for components like aircraft landing gear, engine parts, and turbine blades, where reliability and performance are paramount.

Why Aerospace Engineers Prefer 42crmo4

- Superior fatigue resistance

- Lightweight yet robust structure

- Maintains mechanical properties under thermal cycling

- Excellent impact and vibration resistance

As aerospace designs become more complex and demanding, 42crmo4 continues to deliver the reliability required for critical flight components. Its adaptable mechanical behavior contributes to lower maintenance costs and safer long-term operation.

Oil and Gas Industry: Resisting Corrosive Environments

In the oil and gas industry, components are subjected to not only extreme pressures but also corrosive environments. 42crmo4 material properties make it an excellent choice for critical oil field equipment such as drill rods, pump shafts, and valve components, which must resist both mechanical wear and corrosion from harsh chemicals and fluids.

Key Oil and Gas Applications

- Drill collars and rods

- Tool joints

- Valve stems

- Hydraulic cylinders

The ability of 42crmo4 to withstand high-pressure, high-temperature environments makes it a material of choice for subsea and onshore oil extraction tools. With additional coatings or treatments, it can achieve enhanced corrosion resistance and extended operational life.

General Machinery: Enhancing Mechanical Efficiency

General machinery and manufacturing tools benefit immensely from the strength and fatigue endurance offered by 42crmo4. It is commonly used in machine tool spindles, rotating shafts, and coupling elements. The steel’s workability allows for customized machining without compromising performance.

These components benefit from the steel’s ability to absorb mechanical shocks and vibrations, which are common in dynamic production environments. The performance characteristics of 42crmo4 significantly reduce failure rates and unplanned downtimes.

Table: Comparative Overview of 42crmo4 Applications

| Industry | Common Applications | Desired Material Properties |

|---|---|---|

| Automotive | Gears, crankshafts, axles | High fatigue strength, wear resistance |

| Aerospace | Engine parts, landing gear | Lightweight, thermal fatigue resistance |

| Oil & Gas | Drill rods, valve stems | Corrosion resistance, high tensile strength |

| General Machinery | Spindles, shafts, couplings | Machinability, durability |

| Construction | Bolts, foundation anchors | Load-bearing capacity, ductility |

| Energy | Wind turbine shafts | Fatigue endurance, torsional strength |

| Railway | Drive shafts, brake components | Impact resistance, long service life |

| Marine | Propeller shafts, engine parts | Corrosion resistance, strength under load |

Construction and Infrastructure: Load-Bearing Reliability

Construction applications often demand materials that can support significant loads and endure years of use in challenging environments. The high yield strength and excellent ductility of 42crmo4 material properties make it a go-to for bolts, foundation anchors, and structural supports in construction projects.

Application Benefits in Infrastructure

- Strong load resistance

- Long-term durability in varying weather

- Cost-effective lifecycle performance

- Easily fabricated into precision fastening components

Its predictable performance under static and dynamic loads makes 42crmo4 ideal for critical components in bridges, buildings, and tunnels. With the right surface protection, it also resists environmental degradation.

Renewable Energy: Empowering Wind and Solar Projects

The renewable energy sector, particularly in wind and solar projects, relies heavily on high-strength, fatigue-resistant materials. 42crmo4 material properties are used in the production of wind turbine shafts and gear systems, which must endure continuous mechanical stress and vibrations.

Key Benefits in Energy Sector

- High torsional strength

- Longevity under repetitive motion

- Minimal maintenance requirements

- Ideal for high-torque transmission parts

Railway Sector: Safe and Durable Components

Railway components such as drive shafts, brake discs, and rail fasteners require high strength and impact resistance to endure fluctuating loads and constant motion. 42crmo4 material properties provide the ideal characteristics to withstand dynamic loading and long service intervals in the railway industry.

Railway-Specific Advantages

- Withstands dynamic and impact loads

- Low fatigue wear in high-speed operations

- Stable properties in various climates

- Reduces long-term component fatigue

Modern high-speed trains require components with uncompromised strength and minimal deformation over time. 42crmo4 offers this critical performance advantage, keeping trains safe and efficient.

Marine Engineering: Handling Corrosion and Load

Marine environments are among the most challenging, with components exposed to seawater corrosion and heavy mechanical loads. 42crmo4 material properties ensure that marine parts such as shafts, rudder systems, and propellers continue to perform reliably even under harsh conditions.

Marine Use Benefits

- Resistance to seawater corrosion

- Long-term performance in moist conditions

- Compatible with surface treatments for added protection

- Withstands bending and rotational stress at sea

Shipbuilders and offshore structure engineers prefer 42crmo4 for its predictable behavior in maritime environments, especially when paired with galvanic coatings or cathodic protection systems.

Conclusion

42crmo4 material properties offer a remarkable balance of toughness, strength, wear resistance, and corrosion resilience. These attributes contribute to its popularity in multiple industries including automotive, aerospace, energy, and marine. Whether under thermal stress or mechanical strain, 42crmo4 maintains its integrity, making it a preferred alloy steel in modern engineering applications.

From the skies to the seas, and from renewable energy systems to traditional machinery, the versatility and performance of 42crmo4 make it a strategic choice. As technology and industry evolve, materials like 42crmo4 will continue to play a pivotal role in ensuring reliability and safety across sectors.

FAQ

What is 42crmo4 commonly used for?

It is used in automotive, aerospace, energy, and industrial components such as gears, shafts, and spindles due to its strength and durability.

Is 42crmo4 corrosion resistant?

While not inherently stainless, it has decent corrosion resistance and can be surface-treated for enhanced performance in harsh environments.

Can 42crmo4 be heat treated?

Yes, it responds well to heat treatment processes like quenching and tempering, improving its mechanical properties.

Is 42crmo4 suitable for welding?

Welding is possible but requires careful preheating and post-weld treatment due to the alloy’s high strength.

What makes 42crmo4 better than other steels?

Its combination of high tensile strength, toughness, and wear resistance makes it more reliable in high-stress and precision-demanding applications.