JIYUAN Steel: China’s Premier Special Steel Producer

Table of Contents

Introduction

JIYUAN Steel, officially known as Henan Jiyuan Iron & Steel Group, has established itself as a dominant force in China’s special steel industry. Over the past two decades, the company has undergone a remarkable transformation from a traditional steel producer to a globally recognized manufacturer of high-performance alloy steels. Strategically located in Jiyuan City, Henan Province, JIYUAN Steel supplies premium-grade steel products to critical industries including automotive, aerospace, energy, and heavy machinery.

What sets JIYUAN Steel apart is its relentless focus on technological innovation, stringent quality control, and commitment to sustainable steel production. The company operates multiple state-of-the-art production lines capable of manufacturing over 500 grades of special steel, including bearing steel, gear steel, spring steel, and non-quenched & tempered steel. With annual production capacity exceeding 5 million tons, JIYUAN Steel has become an indispensable supplier to global automotive giants and industrial manufacturers.

This in-depth exploration will cover JIYUAN Steel’s geographical advantages, manufacturing capabilities, product portfolio, market applications, and sustainability initiatives. Additionally, we’ll examine how the company maintains its competitive edge through continuous R&D investment and strategic global expansion.

Strategic Location and World-Class Infrastructure

Geographical Advantages of JIYUAN Steel

JIYUAN Steel benefits tremendously from its prime location in central China’s industrial heartland. The company’s headquarters and primary production facilities are situated in Jiyuan City, which offers multiple strategic advantages:

- Transportation Hub: Jiyuan is connected to major national highways (G55, G3511) and railway networks, including direct access to the Jiaozuo-Zhicheng line. This enables efficient logistics for raw material procurement and finished product distribution.

- Proximity to Key Resources: The region has abundant access to high-quality iron ore from Shanxi province and coking coal from Henan’s local mines, ensuring stable supply chains.

- Industrial Ecosystem: Surrounding cities like Zhengzhou, Luoyang, and Jiaozuo host numerous automotive and machinery manufacturers, creating strong local demand for JIYUAN Steel’s products.

Advanced Manufacturing Facilities

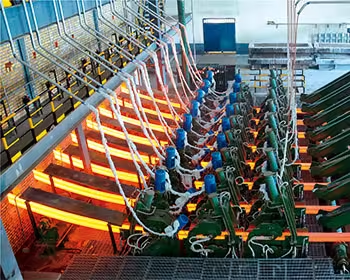

JIYUAN Steel operates one of China’s most modern and environmentally friendly steel plants, featuring:

- Integrated Production Lines: The facility combines ironmaking, steelmaking, and rolling into a seamless process, reducing energy consumption by 15% compared to traditional methods.

- Environmentally Sustainable Operations: The company has invested over ¥3 billion in ultra-low emission technologies, including:

- Active coke desulfurization systems (reducing SO₂ emissions by 95%)

- Closed-loop water recycling (cutting water usage by 30%)

- Waste heat recovery systems (improving energy efficiency by 20%)

- Automation & Robotics: Smart manufacturing systems, including AI-powered quality inspection and automated logistics, enhance precision and productivity.

Cutting-Edge Technology and Product Excellence

Innovative Steelmaking Processes

JIYUAN Steel employs world-leading metallurgical technologies to produce ultra-clean, high-performance steel:

- Electric Arc Furnace (EAF) & Secondary Refining

- Enables precise control of alloy compositions.

- Reduces impurities like sulfur and phosphorus to <0.005%.

- Vacuum Degassing (RH Process)

- Lowers hydrogen content to ≤1 ppm, preventing steel embrittlement.

- Essential for high-end bearing and gear steels.

- Continuous Casting with Dynamic Soft Reduction

- Improves internal steel homogeneity.

- Minimizes segregation in large-diameter billets (up to φ600mm).

Flagship Steel Products and Applications

JIYUAN Steel’s product portfolio is categorized into several high-value segments:

| Product Category | Key Grades | Primary Applications | Industry Standards |

|---|---|---|---|

| Bearing Steel | GCr15, 100Cr6, SUJ2 | Automotive & industrial bearings | ISO 683-17, ASTM A295 |

| Gear Steel | 20CrMnTiH, 8620H | Transmission gears, differentials | SAE J1268, DIN 17210 |

| Spring Steel | 60Si2Mn, 55SiCr | Suspension systems, valve springs | JIS G4801, EN 10089 |

| Non-Quenched Steel | 38MnVS6, C70S6BY | Forged crankshafts, connecting rods | GB/T 15712, ISO 4950 |

| High-Carbon Wire Rod | JGXL86A, SWRH82B | Tire cords, bridge cables | ASTM A510, JIS G3502 |

These materials undergo rigorous testing, including ultrasonic flaw detection, fatigue life analysis, and micro-cleanliness assessment, ensuring they meet the strictest industry requirements.

Market Leadership and Global Expansion

Dominance in Automotive Steel Supply

Automotive manufacturers account for an impressive 70% of JIYUAN Steel’s customer base, demonstrating the company’s strong foothold in this critical sector. The company’s success stems from its ability to provide specialized steel solutions that meet the exacting standards of modern vehicle manufacturing.

For transmission systems, JIYUAN Steel offers gear steels with remarkably narrow淬透性 bandwidth (≤4 HRC), ensuring consistent heat treatment response across large production batches. This level of precision is particularly valuable for manufacturers of automatic transmissions and drivetrain components where dimensional stability is paramount.

The company’s high-strength alloy steels for engine and chassis applications represent another area of excellence. These materials are engineered to withstand the extreme stresses encountered in modern internal combustion engines and vehicle suspension systems. Recent developments include:

- Advanced microalloyed steels that eliminate the need for heat treatment

- Improved machinability grades that reduce tool wear in high-volume production

- Ultra-clean steels with inclusion control for enhanced fatigue performance

With the automotive industry’s rapid shift toward electrification, JIYUAN Steel has developed specialized solutions for electric vehicles, including:

- Lightweight structural steels for battery enclosures

- High-conductivity electrical steels for motor components

- Impact-resistant alloys for critical safety structures

Major Customers:

- Tier 1 Suppliers: Bosch (fuel injection components), Schaeffler (bearing systems), ZF Friedrichshafen (transmission systems)

- OEM Partnerships: Toyota (hybrid vehicle platforms), BMW (premium vehicle architectures), BYD (electric vehicle batteries), Tesla (structural components)

Expanding into Renewable Energy and Infrastructure

The global push toward renewable energy has created significant opportunities for JIYUAN Steel to apply its metallurgical expertise in new markets. In the wind energy sector, the company has become a preferred supplier for critical components:

For wind turbine main shafts, JIYUAN Steel’s 42CrMo4 alloy offers exceptional performance characteristics:

- Fatigue life exceeding 10 million cycles

- Excellent through-hardening properties for large cross-sections

- Consistent mechanical properties across the entire component

The company’s high-purity 100CrMnMoSi8-4-6 steel has become the material of choice for large-diameter bearing applications in offshore wind turbines, where reliability is critical. This grade features:

- Ultra-low oxygen content (<8 ppm)

- Superior carbide distribution

- Excellent dimensional stability under load

In the solar energy sector, JIYUAN Steel provides weather-resistant S355JR structural steel for mounting systems that must withstand decades of outdoor exposure. These materials are optimized for:

- Coastal environments with high salt content

- Extreme temperature variations

- Long-term UV resistance

The company has also developed specialized solutions for energy storage systems, including:

- Corrosion-resistant alloys for battery enclosures

- High-strength framing materials for large-scale installations

- Fire-resistant steels for safety-critical applications

International Growth Strategy

JIYUAN Steel’s export business now spans more than 30 countries across three continents, reflecting the global demand for its high-performance steel products. The company has achieved particularly strong market penetration in:

European Markets:

- Germany: Supplying automotive OEMs and industrial equipment manufacturers

- Italy: Providing specialty steels for high-end machinery and tooling applications

- Scandinavia: Serving the growing offshore wind energy sector

Asian Markets:

- Japan: Supplying precision components for the automotive and electronics industries

- South Korea: Providing steel for shipbuilding and heavy equipment applications

- India: Supporting the country’s rapidly expanding renewable energy infrastructure

North American Markets:

- United States: Supplying structural components for wind turbines and solar farms

- Mexico: Providing automotive steels for the growing manufacturing sector

- Canada: Supporting infrastructure projects and energy development

To strengthen its global presence, JIYUAN Steel has implemented several strategic initiatives:

- Regional Technical Service Centers located in:

- Stuttgart, Germany (European automotive hub)

- Detroit, USA (North American automotive center)

- Yokohama, Japan (Asian technology corridor)

- Joint R&D Programs with leading institutions including:

- RWTH Aachen University (materials science)

- Massachusetts Institute of Technology (manufacturing technologies)

- Tokyo Institute of Technology (energy applications)

- Customized Logistics Solutions featuring:

- Just-in-time delivery systems for automotive customers

- Specialized packaging for overseas shipments

- Inventory management services for key accounts

Sustainable Steel Production and Future Vision

Green Manufacturing Initiatives

JIYUAN Steel is committed to achieving carbon neutrality by 2050 through:

- Hydrogen-Based Steelmaking Pilot (slated for 2026):

- Replaces coking coal with green hydrogen, potentially cutting CO₂ emissions by 80%.

- Circular Economy Practices:

- 95% of steel scrap is recycled.

- Slag byproducts are repurposed for cement production.

Digital Transformation & Smart Factory

The company’s Henan Special Steel Materials Innovation Center is pioneering:

- AI-Powered Predictive Maintenance: Reduces unplanned downtime by 30%.

- Blockchain Traceability: Provides customers with real-time quality data for each steel batch.

Future Product Roadmap

JIYUAN Steel is developing next-generation materials, including:

- Ultra-High-Strength Steels (UHSS) for lightweight electric vehicles.

- Corrosion-Resistant Alloys for offshore wind farms.

Conclusion

From its humble beginnings in 1958 to its current status as a top-three Chinese special steel producer, JIYUAN Steel exemplifies how strategic vision, technological innovation, and sustainability can drive industrial success. By continuously advancing its manufacturing capabilities and expanding into high-growth sectors like renewable energy and EVs, the company is well-positioned to remain a global steel industry leader.

For manufacturers seeking high-performance, reliable steel solutions, JIYUAN Steel offers unparalleled expertise, cutting-edge technology, and a commitment to sustainable progress.

FAQ

Where is JIYUAN Steel’s main production base?

JIYUAN Steel operates its primary production facility in Jiyuan City, Henan Province, China, strategically positioned in an important industrial region with excellent transportation networks and supply chain advantages. The company has also established additional processing centers across major industrial zones to better serve domestic and international customers with efficient logistics and distribution capabilities.

What certifications does JIYUAN Steel hold?

JIYUAN Steel maintains rigorous quality and environmental standards through multiple international certifications, including IATF 16949 for automotive quality management, ISO 14001 for environmental management systems, and API Spec 20E for oil and gas industry standards. These certifications demonstrate the company’s commitment to producing high-quality steel products while adhering to sustainable manufacturing practices across all its operations.

How does JIYUAN Steel ensure product quality?

The company implements comprehensive quality control measures throughout its production process, utilizing advanced testing methods such as ultrasonic flaw detection to identify internal material defects and spectrochemical analysis to guarantee precise alloy composition. These rigorous testing protocols, combined with automated inspection systems and a skilled technical team, ensure that every batch of steel meets the strictest industry specifications and customer requirements.

What are JIYUAN Steel’s most popular export products?

JIYUAN Steel has developed strong international demand for several specialized steel products, with premium-grade bearing steel (GCr15), high-performance gear steel (20CrMnTiH), and durable high-carbon wire rod (SWRH82B) representing its most sought-after export items. These products are particularly valued by global automotive manufacturers and industrial equipment producers for their exceptional fatigue resistance, dimensional precision, and consistent quality performance.

What sustainability measures has JIYUAN Steel implemented?

As part of its environmental commitment, JIYUAN Steel has introduced multiple sustainability initiatives including an advanced waste heat recovery system that conserves approximately 200,000 MWh of energy annually, along with an industry-leading scrap metal recycling program that achieves an impressive 95% recycling rate. These efforts complement the company’s broader environmental protection strategy focused on reducing emissions, minimizing resource consumption, and developing greener production technologies for the steel industry.