Is Lighter Steel Always Better for Automobiles?

Table of Contents

Introduction

Steel is a fundamental material in automobile manufacturing, with a critical role in ensuring safety, performance, and efficiency. Over the years, the push for lighter vehicles has intensified, leading to a growing interest in lightweight steels that offer strength without the bulk. But is lighter steel always better for automobiles? This question goes beyond just weight, touching on various aspects such as strength, durability, cost, and manufacturing processes. In this blog, we will explore the different types of steel used in the automobile industry, the benefits of lighter steel, and whether it truly delivers the best results in automotive design.

Henan Jiyuan Iron & Steel (Group) Co., Ltd. is a leading steel manufacturer, producing high-quality steel that caters to various sectors, including the automotive industry. Our expertise in producing premium-grade steel, coupled with our innovative approach, makes us an ideal partner for automakers looking for the best steel solutions. In this article, we will examine how our steel products support the production of high-performance automobiles.

The Role of Steel in Automobile Manufacturing

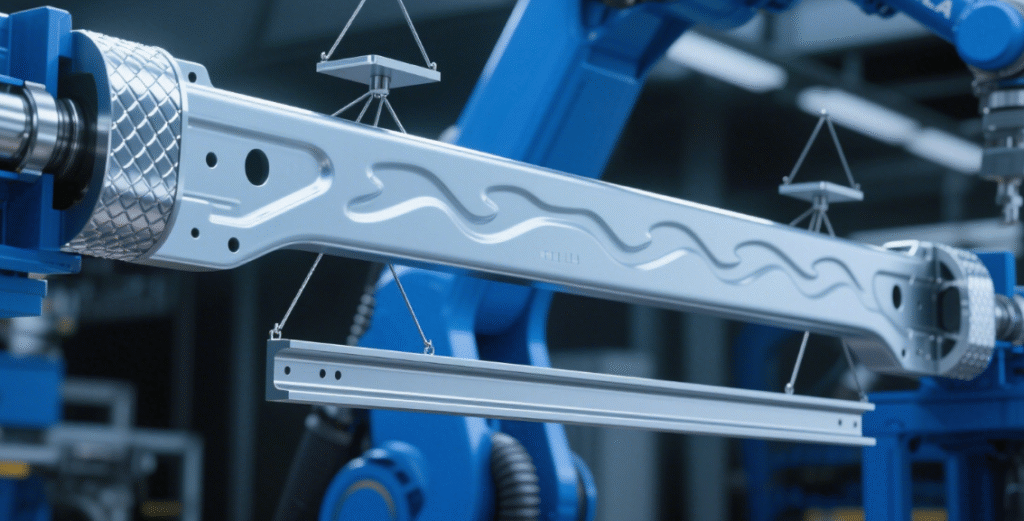

Steel has long been an indispensable material in automobile manufacturing, providing the structural foundation that supports the vehicle’s form, function, and performance. It is used extensively across various parts of the vehicle, from the body and frame to the engine and transmission systems. The versatility of steel in automotive manufacturing lies in its ability to combine strength, durability, formability, and cost-effectiveness, making it a crucial component for automakers striving to meet the demands of modern-day vehicles.

The primary characteristics required for steel used in automobiles include:

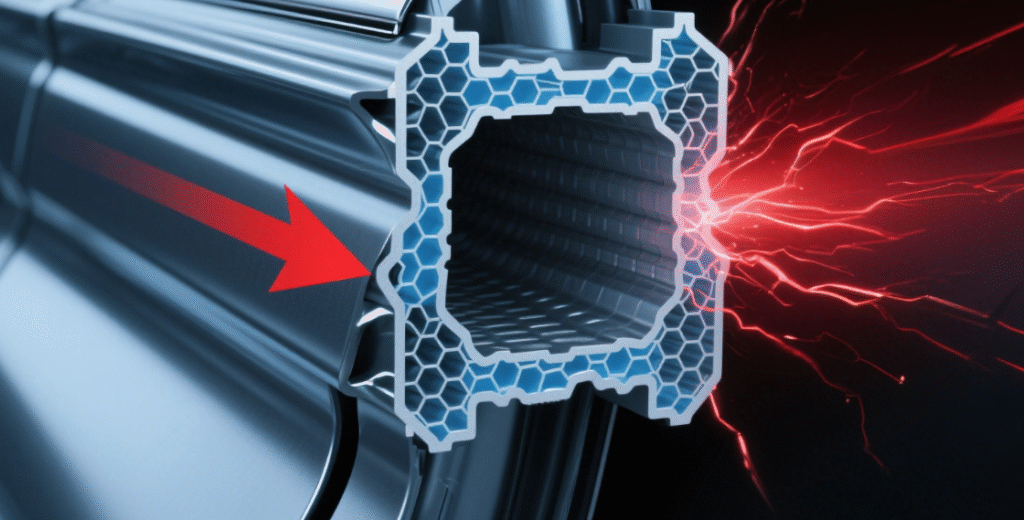

- Strength: Steel must possess the necessary tensile strength to withstand the various stresses and forces that a vehicle undergoes, from road impacts to the weight of passengers and cargo.

- Durability: Steel needs to be resistant to wear, corrosion, and fatigue to ensure that automotive parts last for years without degrading.

- Formability: Steel must be able to be easily shaped and molded into complex automotive components, whether it’s through stamping, casting, or forging processes.

- Cost-effectiveness: While performance is crucial, automakers must keep production costs manageable. Steel provides a relatively affordable option compared to other materials such as aluminum or composites.

Over the years, various types of steel have been used for different automobile applications, but the focus has increasingly shifted toward lightweight steel options. These materials offer the promise of reducing vehicle weight while maintaining—or even improving—strength, durability, and overall performance.

Types of Steel Used in Automobiles

High-Strength Low-Alloy (HSLA) Steel

High-strength low-alloy (HSLA) steel is one of the most commonly used steels in automotive manufacturing today. It is designed to deliver high strength while being lighter than traditional carbon steels. HSLA steel is made by adding small amounts of elements like manganese, nickel, copper, and chromium, which enhance its properties. The result is a steel that offers superior formability and strength while maintaining a lower density, making it ideal for lightweight automotive applications.

Key automotive applications of HSLA steel include:

- Body panels

- Structural components

- Chassis

By using HSLA steel, manufacturers can reduce the overall weight of the vehicle, leading to improved fuel efficiency without sacrificing the vehicle’s strength or performance. This is a significant advantage in today’s market, where automakers are constantly striving to improve environmental performance and meet fuel economy standards.

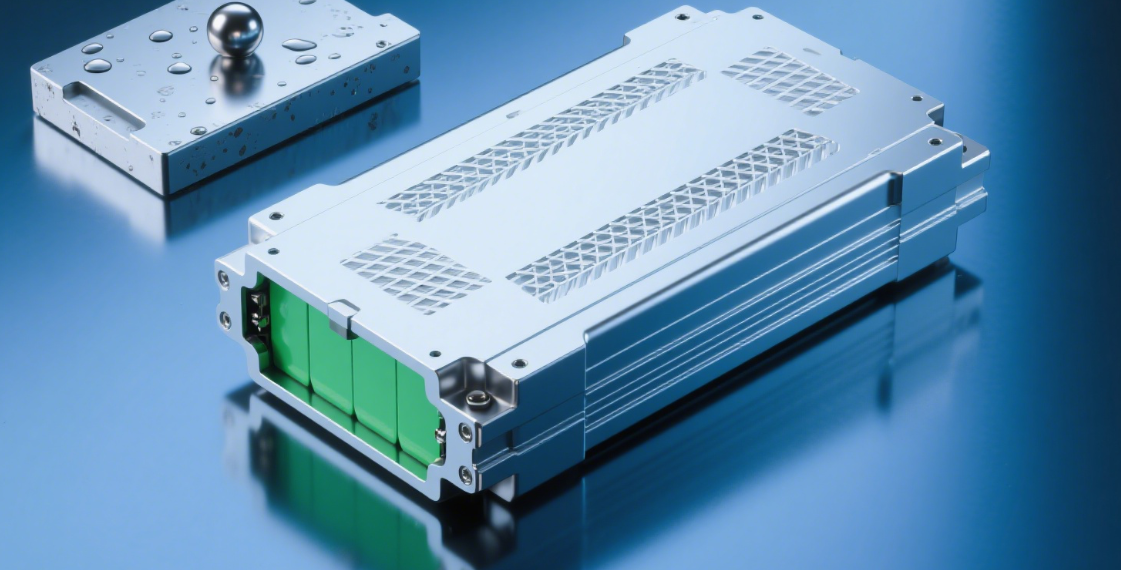

Advanced High-Strength Steel (AHSS)

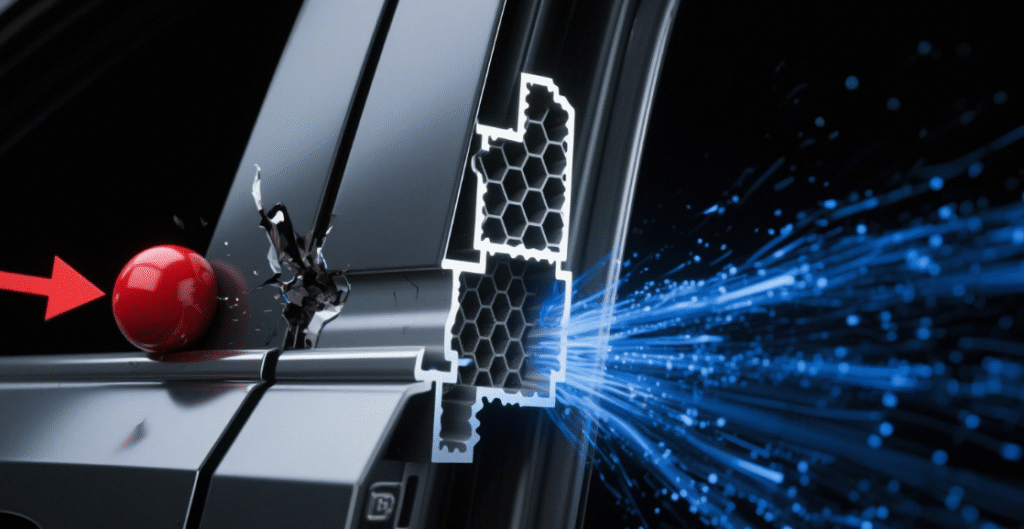

Advanced high-strength steel (AHSS) is another category of steel that has revolutionized the automobile industry. AHSS is engineered to provide exceptional strength and resistance to deformation while maintaining good formability for manufacturing processes. This type of steel offers an improved strength-to-weight ratio, which is key for designing lightweight vehicles that still have the ability to withstand high levels of stress and impact.

Common automotive applications of AHSS include:

- Door panels

- Bumper reinforcements

- Roofs and side structures

AHSS enables automakers to produce cars that are not only lighter but also safer, as it can better absorb energy during impacts. AHSS is a crucial material for meeting modern crash safety standards while still enabling weight reduction.

Stainless Steel

Stainless steel, although heavier than HSLA and AHSS, is still widely used in certain automotive applications due to its superior resistance to corrosion and durability. In applications where the material will be exposed to high temperatures, moisture, or corrosive elements, stainless steel is often the best choice.

Typical uses for stainless steel in automobiles include:

- Exhaust systems

- Trim pieces

- Engine components

Stainless steel’s resistance to rust and corrosion makes it the material of choice for parts exposed to extreme conditions, such as the exhaust system, which is constantly subjected to high heat and exhaust gases.

Alloy Steel

Alloy steels are created by adding elements such as chromium, vanadium, molybdenum, and nickel to carbon steel. These alloys give the steel greater strength, toughness, and resistance to wear. In the automotive industry, alloy steel is typically used in parts that require high performance and resistance to fatigue.

Alloy steel is commonly used in:

- Engine components (like crankshafts and camshafts)

- Gears

- Drive shafts

Alloy steel’s ability to handle the extreme forces involved in engine and drivetrain applications makes it a critical material for automakers who require parts that can endure high stress without failure.

Benefits of Lighter Steel in Automobiles

As the automobile industry has evolved, the focus has increasingly shifted toward lightweight materials that offer better performance, fuel efficiency, and environmental benefits. Lighter steel offers many advantages for both manufacturers and consumers.

Improved Fuel Efficiency

One of the key motivations behind using lighter steels in automobile manufacturing is the ability to significantly reduce fuel consumption. Lighter vehicles require less energy to accelerate and maintain speed, which directly translates into better fuel efficiency. Reducing the overall weight of the car can help automakers meet the stringent fuel economy regulations that have been implemented in many regions globally.

By replacing heavier materials with lightweight steel alternatives such as HSLA and AHSS, manufacturers can produce vehicles that consume less fuel, emit fewer pollutants, and perform better in terms of energy efficiency. With the automotive industry under pressure to reduce its carbon footprint, lightweight steel options are seen as an effective way to achieve sustainability goals.

Enhanced Performance

Lighter vehicles also offer enhanced performance on the road. A lighter vehicle can accelerate faster, handle more responsively, and achieve higher speeds. For performance vehicles, such as sports cars, weight reduction is a critical factor in improving acceleration, braking, and handling. Lighter vehicles tend to have better weight distribution and balance, which enhances their overall driving dynamics.

Additionally, lighter materials reduce the strain on suspension systems and brakes, resulting in improved ride comfort and handling. These performance benefits, combined with weight reduction, are becoming increasingly important to consumers looking for both eco-friendly and high-performance vehicles.

Reduced Environmental Impact

With growing concerns about climate change and air pollution, reducing a vehicle’s carbon footprint has become a primary focus for both automakers and consumers. Using lighter steel in vehicle construction can contribute significantly to reducing fuel consumption, which in turn lowers emissions.

Automobile manufacturers that adopt lighter materials such as HSLA and AHSS help contribute to the reduction of greenhouse gases by producing cars that consume less fuel and emit fewer pollutants. This is especially important as governments worldwide are tightening emission regulations and pushing for a shift toward greener vehicles.

Incorporating lightweight steel into vehicles is one of the most practical ways for automakers to comply with these regulations while also meeting consumer demand for environmentally-friendly transportation options.

Table: Comparison of Steel Types for Automobiles

| Steel Type | Weight | Strength | Formability | Cost | Applications |

|---|---|---|---|---|---|

| HSLA Steel | Light | High | Excellent | Moderate | Body panels, structural components, chassis |

| AHSS | Very Light | Very High | Good | High | Bumper reinforcements, side structures, door panels |

| Stainless Steel | Heavy | High | Moderate | High | Exhaust systems, trim pieces, engine components |

| Alloy Steel | Moderate | Very High | Good | Moderate | Engine parts, gears, drive shafts |

The Trade-Off: Is Lighter Always Better?

While lighter steel offers several benefits, such as increased fuel efficiency and reduced environmental impact, it is not always the best choice for every application. For certain high-stress components, such as engine blocks, axles, and suspension systems, heavier, stronger steel may be required to ensure vehicle safety and long-term durability.

Moreover, lighter steels like HSLA and AHSS can sometimes be more expensive than traditional carbon steel. This cost trade-off is an important consideration for automakers, especially when balancing the desire for weight reduction with the need to maintain a competitive price point.

Conclusion

The push for lighter vehicles has led to the increased adoption of advanced steel materials in automobile manufacturing. Lighter steels like HSLA and AHSS provide excellent performance in terms of fuel efficiency, handling, and safety. However, the decision to use lighter steel should be made based on the specific needs of the vehicle and the parts being manufactured.

At Henan Jiyuan Iron & Steel (Group) Co., Ltd., we specialize in providing high-quality steel solutions that meet the needs of various industries, including the automotive sector. Our products are designed for high performance, durability, and cost-effectiveness. Whether you need HSLA, AHSS, or other specialized steel types, we have the expertise and technology to support your manufacturing processes.

If you’re looking to incorporate premium-grade steel into your automotive designs, feel free to contact us for more information and quotations. Our team is ready to assist you in finding the perfect steel solutions for your needs.

FAQ

How does steel contribute to vehicle safety?

Steel is used in critical parts such as the frame, body panels, and suspension systems, providing the strength and durability needed to withstand impact in the event of a crash. The right steel type ensures that a vehicle maintains its structural integrity during a collision.

What is the difference between HSLA and AHSS?

HSLA (High-Strength Low-Alloy) steel is lighter and more cost-effective, while AHSS (Advanced High-Strength Steel) offers superior strength and is more suitable for high-stress components. AHSS is typically used in areas requiring exceptional strength, like door reinforcements and side impact zones.

Why is stainless steel used in automobiles despite its weight?

Stainless steel is highly resistant to corrosion and high temperatures, making it ideal for exhaust systems and engine parts that are exposed to harsh conditions. Its durability ensures a longer lifespan for these components.

How can I get a quote for high-quality steel for my automotive project?

You can easily contact us at Henan Jiyuan Iron & Steel (Group) Co., Ltd. through our website or by phone. Our team will provide you with a tailored quote based on your specific needs.