5 Essential Steel Round Bar Standards You Must Know

Table of Contents

Introduction

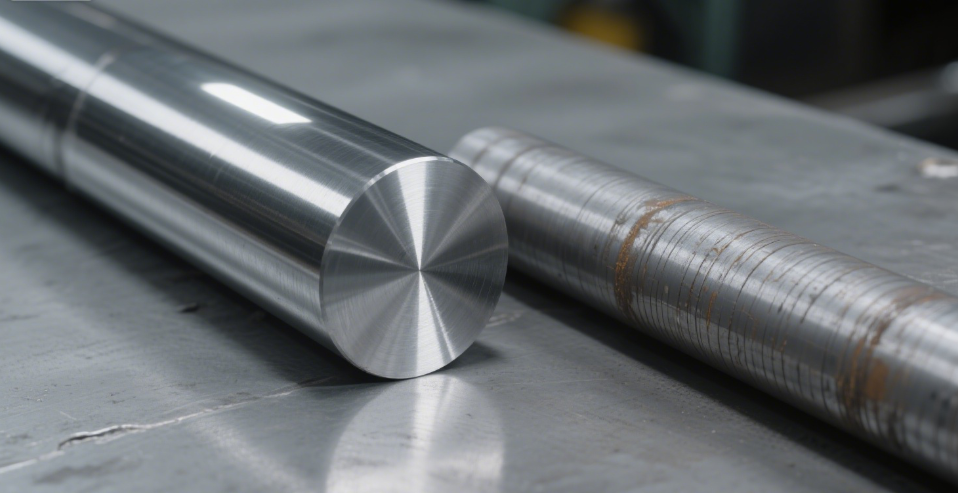

Steel round bars are a versatile material used in a wide variety of industries, including construction, manufacturing, automotive, and aerospace. These bars are available in different grades and sizes, with various standards governing their specifications to ensure consistency, quality, and suitability for specific applications.

In this blog, we will dive deep into the essential steel round bar standards you need to know. From understanding dimensional tolerances to the importance of material grades, we’ll guide you through the key factors that influence purchasing decisions. Whether you’re a buyer, manufacturer, or engineer, mastering these standards is crucial for ensuring optimal performance and value in your projects.

1. Understanding Steel Round Bar Dimensions and Tolerances

When it comes to steel round bars, dimensioning is one of the most critical aspects in determining the product’s functionality and performance. The size and shape of the bar directly impact its fit in machinery, equipment, and tools, making precision paramount in ensuring that the end product performs as expected.

Key Dimension Standards

Steel round bars typically follow standardized dimensions defined by globally recognized standards such as ASTM, DIN, and JIS. These standards ensure that the nominal diameters and lengths of the bars are within strict tolerances, allowing for uniformity across production batches and preventing discrepancies that could lead to operational issues.

| Standard | Nominal Diameter Range | Tolerance |

|---|---|---|

| ASTM A108 | 0.250” to 24” | ±0.031” to ±0.250” |

| DIN 1013 | 8 mm to 100 mm | ±0.15 mm |

| JIS G 4303 | 10 mm to 120 mm | ±0.20 mm |

These dimension specifications ensure that steel round bars will fit accurately in their intended applications, including critical functions like coupling, bearing housing, and mechanical operations. Inaccurate dimensions can lead to equipment misalignments, performance failures, and even safety hazards.

Importance of Dimensional Accuracy

Achieving precise dimensions within the defined tolerances is essential for the mechanical integrity and performance of steel round bars. Bars that fall outside of these tolerances may not fit correctly in assemblies, leading to operational inefficiencies, mechanical failures, or higher maintenance costs. For example, bars that are too large might require further machining, while bars that are too small could compromise the strength of the equipment they are used in.

2. Steel Round Bar Grades and Material Composition

Steel round bars come in a variety of grades, with each one designed to meet the specific mechanical, chemical, and performance requirements of different applications. The grade of steel used can significantly affect the bar’s strength, ductility, weldability, and resistance to corrosion, making it essential for buyers to understand the material composition before making a purchase.

Common Material Grades

- Carbon Steel: Carbon steel is one of the most widely used materials for steel round bars. It is an affordable option that offers a balance between strength, ductility, and cost-effectiveness. These bars are commonly used in general-purpose applications, where high strength or corrosion resistance is not a critical factor.

- Alloy Steel: Alloy steel round bars contain elements such as chromium, molybdenum, and nickel, which are added to enhance properties like hardness, strength, and wear resistance. These bars are ideal for applications in demanding industries, including automotive, aerospace, and manufacturing, where high-performance materials are essential.

- Stainless Steel: Stainless steel is known for its excellent corrosion resistance, making it suitable for harsh environments, such as in the marine, chemical, and food processing industries. These bars are often used in applications that require both strength and resistance to corrosion.

Key Properties of Different Grades

| Grade | Chemical Composition | Applications | Key Properties |

|---|---|---|---|

| AISI 1018 | Carbon Steel, 0.18% Carbon | General-purpose structural uses | Good weldability, moderate strength |

| AISI 4140 | Alloy Steel, Chromium, Molybdenum | Automotive, oil & gas industries | High strength, fatigue resistant |

| AISI 316 | Stainless Steel, 16-18% Chromium | Chemical processing, marine industries | Excellent corrosion resistance, non-magnetic |

Understanding the properties of each steel grade ensures that buyers can select the right material for their needs. For instance, AISI 1018 is often used in less-demanding environments, while AISI 4140 and AISI 316 are more suited for heavy-duty and corrosion-resistant applications, respectively.

3. Heat Treatment Standards for Steel Round Bars

Heat treatment plays a crucial role in altering the physical and mechanical properties of steel round bars, improving characteristics like hardness, strength, and wear resistance. The process can also make steel easier to machine or improve its ability to withstand high-temperature environments.

Common Heat Treatment Processes

- Annealing: This heat treatment process softens the steel, making it more ductile and easier to machine. It is typically used for carbon steel bars and can help improve machinability by reducing the hardness of the material. After annealing, the material can be more easily worked into its final shape.

- Quenching and Tempering: Quenching involves heating the steel to a high temperature and then rapidly cooling it, typically in water or oil, to harden the material. Tempering follows, where the steel is reheated to a lower temperature and then cooled to relieve stresses. This process is commonly used in alloy and stainless steel bars to enhance their strength while maintaining adequate toughness.

- Normalizing: In this process, steel is heated to a specific temperature and then air-cooled. Normalizing refines the grain structure, reduces internal stresses, and ensures uniformity across the material. This process is typically used when the material’s strength and toughness need to be enhanced.

Importance of Heat Treatment

Heat treatment processes enable steel round bars to meet specific strength and hardness requirements for demanding applications. For example, quenching and tempering can significantly increase the wear resistance of bars used in heavy machinery, while annealing is often used to prepare bars for easier machining without compromising material integrity.

4. Surface Finish Requirements

The surface finish of steel round bars is not only an aesthetic factor but also plays a significant role in their functional performance. A high-quality surface finish can reduce the risk of fatigue failure, improve corrosion resistance, and enhance the overall durability of the steel bars.

Surface Finishing Processes

- Cold Drawn Finish: Cold drawing involves pulling the steel bar through a die at room temperature to achieve precise dimensions. This process produces a smooth, polished surface with minimal imperfections. Cold drawn bars are ideal for applications that require a high level of dimensional accuracy and smooth surface characteristics.

- Hot Rolled Finish: Hot rolling involves heating the steel to high temperatures and then passing it through rollers to achieve the desired size. While the surface finish of hot-rolled bars is slightly rougher than that of cold-drawn bars, it is a more cost-effective process, especially for larger diameter bars.

- Polished Finish: A polished finish is typically used for steel round bars intended for aesthetic applications, such as in the food industry or decorative products. It provides a shiny, smooth surface that enhances the appearance of the material.

Why Surface Finish Matters

The surface finish plays a critical role in the material’s performance. A smoother surface finish reduces the chances of fatigue failure in bars that will be subjected to dynamic loads or harsh conditions. On the other hand, a rougher finish may be necessary for applications where friction is required, such as in gears or cams.

5. Inspection and Testing of Steel Round Bars

To ensure that steel round bars meet the required quality and performance standards, manufacturers perform rigorous testing and inspections. These tests verify that the bars comply with the necessary mechanical and chemical specifications, ensuring they will perform as expected in their end-use applications.

Common Testing Methods

- Ultrasonic Testing (UT): This non-destructive testing method is used to detect internal defects such as cracks, voids, or inclusions that could compromise the structural integrity of the bar. It is essential for ensuring that bars meet the highest standards of quality, especially when used in critical applications.

- Tensile Testing: This test measures the bar’s ability to withstand tension. It determines the ultimate tensile strength and the yield point of the material, which are crucial for ensuring that the steel will perform as expected under load.

- Hardness Testing: Hardness tests, such as the Rockwell or Brinell test, determine the material’s resistance to indentation and deformation. This is particularly important for assessing the wear resistance of steel round bars.

Importance of Testing

Inspection and testing are vital for ensuring the strength, durability, and safety of steel round bars, especially when used in high-stress environments. Rigorous testing ensures that any potential defects are identified and corrected before the bars are used in critical applications, avoiding the risk of mechanical failures.

FAQ

Q1: What is the difference between ASTM and JIS standards for steel round bars?

ASTM and JIS are two different standards organizations. ASTM (American Society for Testing and Materials) is primarily used in the United States, while JIS (Japanese Industrial Standards) is prevalent in Japan. Both have similar specifications for steel round bars, but the testing methods and some grade compositions may differ.

Q2: Why is the surface finish important for steel round bars?

The surface finish of steel round bars affects both their aesthetic and mechanical properties. A smoother surface finish reduces wear and tear, improving the bar’s performance in high-stress environments, while a rougher finish may be preferred for specific applications like gears and shafts.

Q3: How does heat treatment affect steel round bars?

Heat treatment enhances the mechanical properties of steel round bars. Processes like quenching and tempering can increase strength and hardness, while annealing makes the material easier to machine.

Q4: Can steel round bars be used for aerospace applications?

Yes, certain grades of steel round bars, particularly alloy and stainless steel, are used in the aerospace industry due to their high strength, corrosion resistance, and reliability in critical applications.

Conclusion

Understanding the essential standards for steel round bars is crucial for anyone involved in the procurement, manufacturing, or application of these materials. Whether you are selecting the right grade for your project, ensuring dimensional accuracy, or choosing the appropriate heat treatment, these standards help ensure the final product meets the necessary performance requirements.

By paying attention to these key factors—dimensions, material grades, heat treatments, surface finishes, and inspection protocols—you can make informed decisions that will lead to better outcomes for your projects.